Why Is Quality Control Important?

Remember, the key is people. We can put perfect processes in place, but the people either make it or break it. Warehouse quality control does have steps to help guide you through the processes, but empowering the people at each stage is the key to optimal performance.

You can’t assume that the departments handling the product before you followed the same quality control procedures. Still, the buck will stop with you — the first person in the chain of command who follows QA procedures and takes responsibility for what you can control. Without empowering every employee in the chain to take charge of their jobs, you’ve already located your weak link(s).

Here’s a quality control process that can work as a checklist for a production warehouse inspection:

- Safety Check: This should be your first and last item in warehouse quality control. Make sure the conveyor belts — or whichever part of the production chain you’re linked to — are operating correctly and that no safety hazard poses a threat to employees. Every warehouse quality control plan must include detailed safety procedures.

- Inspect Materials When Received: Whether you’re in Receiving and inspecting the raw materials and products your company uses; in Shipping where a conveyor belt feeds boxes being sent out; or working on the production line itself, inspect, inspect, inspect.

- Prior to Full-Production Inspections: Pull one finished product and inspect. If it passes muster, proceed with the run.

- Inspection During Normal Production: At intervals, pull a partially finished product and inspect.

- After Production Inspections: A predetermined quantity of product will be pulled and inspected.

- QA Leader Inspection: The person with final authority will inspect the product before shipping. This quality control process is an ongoing and ever-evolving activity. You must evolve, too, to meet new, more significant inspection challenges.

- Safety Check:One last item of great importance, especially if another shift will come online — the safety inspection! Ensure any hazards are removed and the all-clear is given.

While this list follows a production line, the shipping department’s efforts are also critical, as they are the last line of defense against error. And if you are a distribution center only, the conveyors full of boxes and packages act as your production line.

What Does Quality Control Mean?

While there are many correct answers to this question, the focus should always be on the people more than the process. Taking time to ask yourself, “What does quality control mean?” is a great exercise to revisit often. Of course, as a business, you need steps to follow and regular assessments of your product’s quality to remain successful. But quality control is more than a list of rigid rules. It should be more than just a list of quality control methods that work. Overall, quality control means:

- Every employee understands their roles and job requirements and can fulfill them with competence.

- Every employee is empowered to make decisions that can affect production or distribution to make sure the product — at their point in the production process — is correct.

- Every employee takes responsibility that every product at their station is accurate, and if not, calls attention to it or fixes it themselves.

- Everyone — including upper management — cares about 100% correct products leaving their company every time.

It’s this type of commitment that ensures a quality warehouse and a 100% correct product reaching the end-user.

How to Create a Quality Control Process

Now that you have your employees empowered to bring the kind of change you want, it’s time to create a quality control process. Span Tech has developed a safety-first working environment based around people. People are our heart and soul. They’re the reason our quality control is a seamless process, resulting in the highest quality products for our customers. Span Tech’s Quality Promise follows these seven principles:

- 1. Personnel: Be sure to hire and retain top-quality employees, then put the right people in the right places. When well-placed employees are empowered, you’ll see them take ownership of their link in the production chain. And that’ll make all the difference in warehouse quality control.

- 2. Relationships: Value the relationships you develop with your suppliers. Still, make sure they meet your rigorous standards regarding the products and raw materials you purchase. If there’s a problem, offer practical solutions to resolve it quickly.

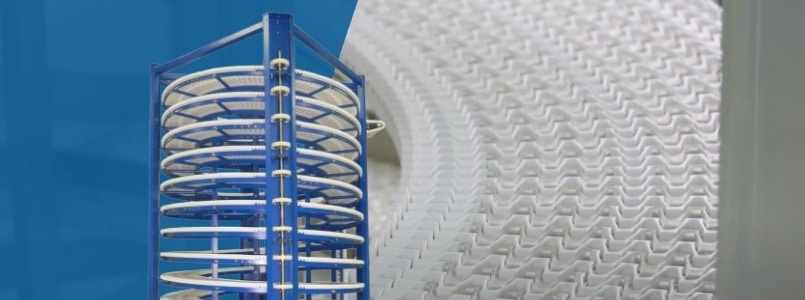

- 3. Technology: Span Tech is a leading innovator of conveyor solutions because of the people we count on every day using the first-class equipment and warehouse quality control procedures already in place. Be sure to give your employees state-of-the-art technology and equipment, so they can produce top-shelf products.

- 4. Documentation: Take the time to record and ensure your quality control procedures are clearly defined for each stage of your production. Whether in-house job instructions or engineering and design projects, produce accurate, understandable, and consistent documentation across all departments. If even one employee can’t clearly understand the instructions they’re to follow, work with that person to determine if the documentation needs reworking. Always retain good people — documentation is easier to replace.

- 5. Verification: Stay committed to making sure your products work as intended and are correct to the finest detail. Use appropriate measuring tools when testing to be confident each product is as it should be. If a product doesn’t meet high standards, your customers should never be the ones to tell you.

- 6. Dedication: Quality control methods would be meaningless without committed and empowered employees. The power behind Span Tech is our people. Like us, you’ll need competent, empowered employees who do things the right way every time. Their dedication makes it possible for you to offer the highest quality products and services to your customers.

- 7. Practice Prevention: Catching and solving problems before they leave your facility is critical to success. Taking appropriate actions to avoid defects starts with clearly understanding your customers’ requirements. What they expect should be your standard and the baseline of your production. Go above and beyond their requirements with unwavering quality and reap the benefits of success.

Safety is a Quality Control Process

A safe working environment is critical to any quality control process. As you put these inspection techniques in place, remember that safety must come first! We designed our conveyor systems with that in mind. Our EZGUIDE™ Conveyor Guide Rails replaces the brackets or rods that most conveyor belts have. These brackets and rods often stick out from the sides when the belt is in the “retracted” position. That poses a safety hazard in any warehouse or distribution center. With this type of safety hazard, warehouse quality control is already lost due to the dangers posed to employees by their conveyor belts.

EZGUIDE™ has no mechanical components protruding from the sides during adjustment. And EZGUIDE™ GUIDE RAILS remain adjustable through conveyor belt curves. If you believe people are your company’s heart and soul, any quality control process must start with ensuring their safety. That commitment has helped Span Tech become an industry leader as an innovative manufacturer of conveyor belts.

Span Tech and Warehouse Quality Control

Developing a warehouse quality control program is much easier when recognizing your employees are your number one asset. Instead of identifying “things” to change or rearrange, identify people. Placing the right person in the right job will help prevent defects before your checklist even begins. Put the best people in the safest environment and give them clearly defined roles and responsibilities while empowering them to make decisions. Quality control procedures will flow organically as you make a step-by-step map of your entire production or distribution procedures. Finally, hiring or identifying the right employee for the job of making the final inspection is highly important. They’re the last person to see the product before it ships out to the end-user.