B2B vs. B2C: A Brief Overview

How do B2B and B2C compare and differ? In this section, we define each warehouse category and examine the challenges they face.

What is a B2B Warehouse?

A warehouse that specializes in business to business (“B2B”) orders typically sends products in bulk on a recurring basis. Simply put, the warehouse is sending items from its manufacturing business to another business.

For example, if a company needs supplies for the coming year, a B2B warehouse can deliver a large quantity of products for employees to have on hand. That way, team members will have essential items in stock to run their business.

Since B2B fulfillment consists of frequent, bulk orders, accuracy plays a key role. Additionally, shipments sent via sea freight, air freight or ground can be expensive and require longer delivery lead times. Along with that, longer lead times and overseas suppliers need to be considered during the receiving process in a B2B warehouse. With all of this at stake, order errors can be costly and result in a loss of company time.

It’s also important to note that a business may also have compliance restrictions, and B2B warehouses need to prove they can meet those requirements. Examples include tax rules, barcodes, parcel labels and invoices.

What is a B2C Warehouse?

Business to consumer (the “B2C” meaning) involves a company offering products for individual customers rather than other businesses. As a result, a B2C warehouse oversees large volumes of orders with smaller quantities of product in each order. This is different from B2B orders which tend to contain mass quantities of items.

In our fast paced world, many consumers expect their delivery within the same day or soon after. When it comes to the receiving process in a B2C warehouse, it’s important to note that customers have less tolerance for delays. With this in mind, B2C fulfillment requires a great deal of accuracy and speed. Additionally, a B2C warehouse is more likely to have to handle returns than a B2B warehouse. As a result, B2C warehouses need the latest technology and foolproof management systems to monitor shipments.

Since B2C warehouses take customer experience into consideration, they may also offer special packaging features, like tissue paper, gift wrapping or personalized greeting cards.

Responding to the Pandemic’s Impact on the Manufacturing Industry

Problems in the manufacturing industry due to COVID-19 have led to reduced demand and disrupted supply chains. But they’ve also presented opportunities for growth, innovation and competitive advantage in the industry. To bounce back from the impact of COVID-19 on manufacturing industries, we recommend your facility does the following:

B2B Fulfillment vs. B2C Fulfillment

Now that you know the basics of B2B vs. B2C, let’s examine how they differ when it comes to fulfilling and delivering orders.

Pre-Purchase Stage

When it comes to the pre-purchasing stage, B2B and B2C warehouses differ in the following ways:

- Revenue per order. As we mentioned earlier, B2B shipments tend to contain products in bulk, while B2C usually handles smaller orders, like clothing, a book or an electronic appliance. As a result, a B2B delivery is typically worth more in revenue than a B2C delivery.

- Price per product. Generally, when a B2B transaction occurs, the price is agreed upon based on factors like recurring orders and the duration of the working relationship. In comparison, B2C transactions consist of standard prices set for every consumer.

Purchase Stage

During the point of purchase, B2B and B2C warehouses face differences when it comes to the:

- Sales process. Typically, B2B transactions consist of a company comparing prices from different warehouses and selecting the most cost-effective, reliable supplier. This is usually not the case for B2C warehouses because customers don’t consider or choose which warehouse their products come from.

- Order size. Since B2B orders are normally bulky, they often require machinery and packaging materials durable enough for safe transportation. While B2C warehouses still require reliable equipment, they generally handle lighter shipments that are easier to package and deliver.

- Payment. While B2B payments normally involve the obtaining of materials on credit, B2C transactions are more transforward, and payments occur during purchase.

Post-Purchase Stage

After a purchase is made, it’s up to B2B and B2C warehouses to gather and ship the product. While both must work to fulfill their orders, they handle the following things differently:

- Shipping methods. Since B2B shipments are bulkier and take longer to reach their destination, they often require delivery via specialized trucks, planes or ships. In comparison, B2C shipments usually arrive much sooner and are delivered by truck.

- Customer relationships. B2B transactions tend to be recurring, which makes the concept of a business partnership crucial for both parties involved. This isn’t as true in the B2C industry where a customer can choose. Since B2C transactions between a single business and consumer aren’t as routine, establishing a partnership isn’t as vital.

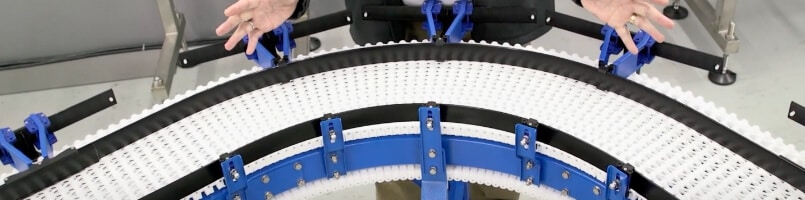

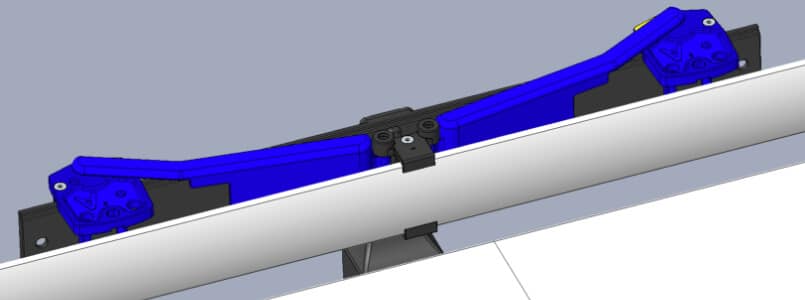

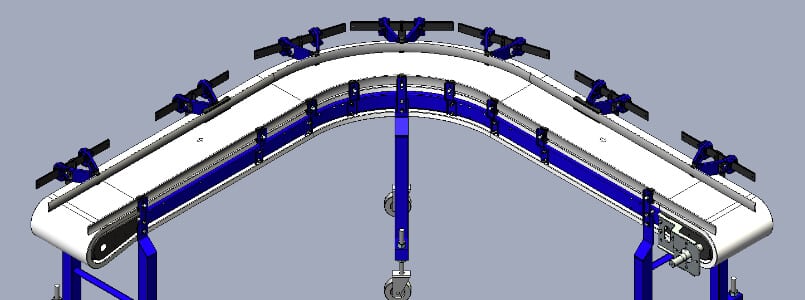

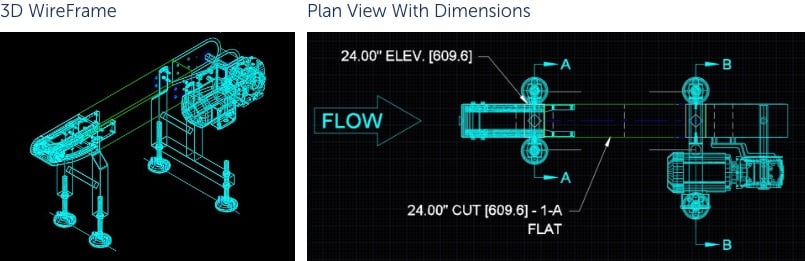

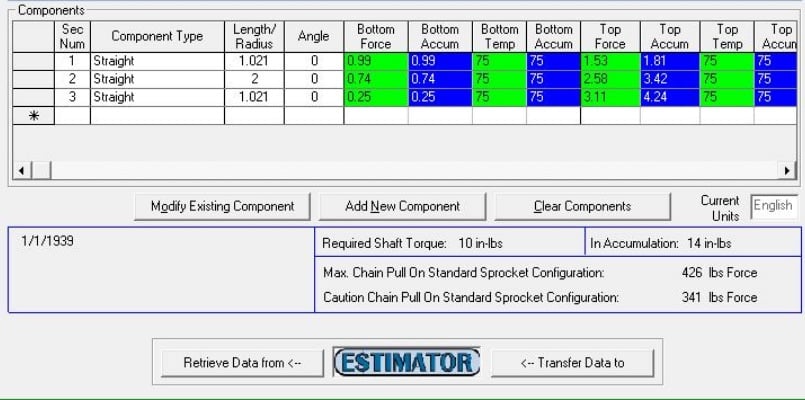

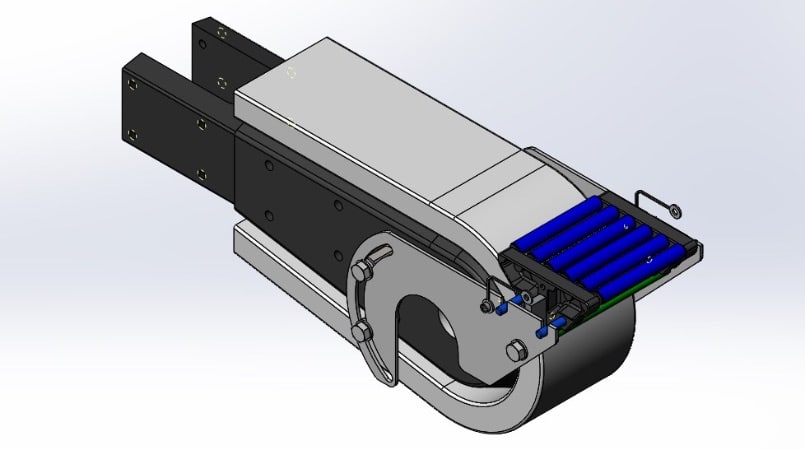

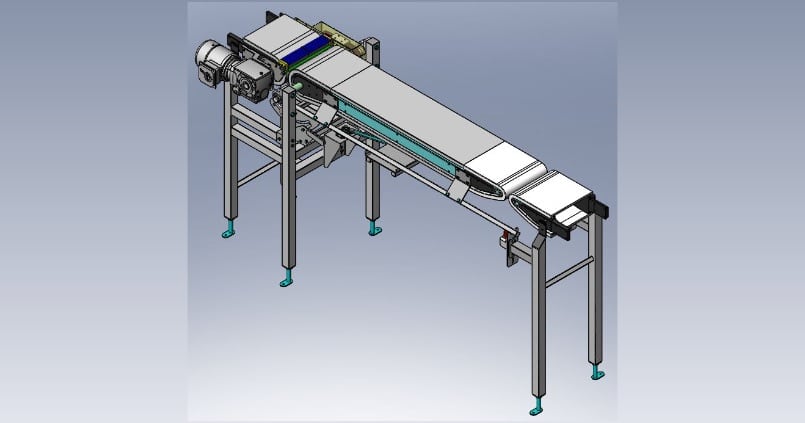

Make the Most of Your B2B & B2C Fulfillment with Custom Conveyor Solutions from Span Tech

Knowing the difference between B2B vs. B2C warehouse requirements can help you make the right decisions for your facility. From B2B to B2C, Span Tech is proud to help a variety of industries meet their manufacturing needs. With years of experience and a passion for creating innovative solutions, our team makes it their mission to see your warehouse thrive. To get the most out of your B2B or B2C warehouse with premium, state-of-the-art equipment, start your estimate today!