What Is an E-Commerce Conveyor?

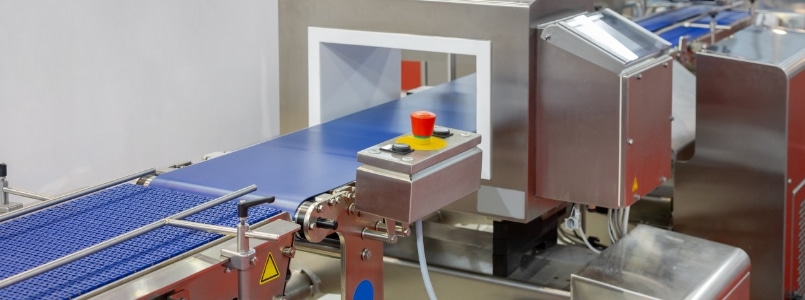

An e-commerce conveyor is a type of conveyor system specifically designed for use in e-commerce distribution centers, warehouses, fulfillment centers and other facilities.

E-commerce conveyors are designed to handle a wide variety of products, including small packages, large boxes and irregularly shaped items. They can be used for a range of tasks, including order picking, sorting, packing and shipping.

Some of the key features of e-commerce conveyors include:

- High-speed operation

- Modularity

- Scalability

- Flexibility

They can be configured to fit the specific needs of the facility, and they can be easily modified or expanded as the business grows or changes.

E-commerce conveyors play a critical role in the efficient and effective operation of e-commerce facilities, helping businesses meet the demands of their customers and stay competitive in the market.

Why Is a Conveyor System Necessary for E-Commerce?

In the fast-paced world of e-commerce, order fulfillment and delivery speed are critical factors in customer satisfaction. To keep up with the demand for faster and more efficient order processing, companies must optimize their e-commerce warehouse and distribution center operations. One essential element in achieving this goal is the use of conveyor systems.

Conveyor systems offer a highly automated and efficient means of transporting products throughout an e-commerce fulfillment warehouse. They can handle a wide range of products, from small items to large and bulky items, and can transport them quickly and safely from one area to another. With the use of conveyor systems, e-commerce companies can significantly reduce the time and labor required to move products from one location to another.

In addition, conveyor systems allow for greater control and visibility over product flow, enabling companies to track inventory and order status more accurately. This can help to reduce errors, minimize order fulfillment times and improve customer satisfaction.

What Are the Benefits of an E-Commerce Conveyor System?

A conveyor system is essential for e-commerce facilities for several reasons:

- Improved Efficiency: An e-commerce conveyor system can significantly increase the speed and efficiency of order fulfillment processes. With a conveyor system, items can be transported quickly and accurately from one location to another, reducing the time required for order processing and shipment.

- Increased Productivity: Automated conveyor systems can handle large volumes of products, which helps to increase productivity and throughput. E-commerce automation workers can focus on tasks such as picking and packing rather than moving products from one location to another.

- Better Accuracy: A conveyor system can help improve order accuracy by reducing the likelihood of errors that can occur when products are manually transported. With an automated conveyor system, products are transported with precision, reducing the chances of misplaced or damaged items.

- Flexibility: E-commerce conveyor systems can be customized to fit the specific needs of the facility. This means that the system can be adapted to handle different types of products and accommodate changes in the business’s needs.

- Reduced Costs: By reducing the amount of manual labor required for order fulfillment, a conveyor system can help businesses save on labor costs. Additionally, by improving efficiency and throughput, businesses can fulfill more orders and generate more revenue.

What Types of Conveyors Are Most Suitable for E-Commerce?

E-commerce involves handling many different types of products. Therefore, choosing the right type of conveyor for e-commerce can be a challenging task. Here are some types of conveyors that are most suitable for an e-commerce warehouse or distribution center:

- Belt Conveyors: Belt conveyors are commonly used in e-commerce because they are versatile and can handle a wide range of products. They are ideal for transporting packages, boxes and other items.

- High Speed Switch Conveyors: High speed switch conveyors are essential for e-commerce facilities that demand rapid and accurate diversion of products between conveyor lines. These conveyors excel in optimizing material handling operations, facilitating seamless sorting and distribution of items.

- Sortation Conveyors: Sortation conveyors are designed to sort products based on their size, shape and weight. They are the perfect solution for e-commerce distribution centers or warehouse that require high-speed sorting and distribution of products.

- Vertical Conveyors: Vertical conveyors are suitable for transporting products vertically between different levels of an e-commerce distribution center or warehouse. They are the perfect conveyor for multi-level order picking and storage.

- Automated Guided Vehicles (AGVs): AGVs are ideal for e-commerce applications that require flexible and autonomous material handling. They can transport a wide range of products, including small and large items, within an e-commerce warehouse or distribution center.

What Types of Sortation Equipment Are Best for E-Commerce Conveyors?

Sortation equipment is an essential component of conveyor systems in an e-commerce operation. Conveyor sorter systems allow for the rapid and accurate sorting of products, ensuring that orders are fulfilled quickly and efficiently.

Here are some types of sortation equipment that are best suited for e-commerce conveyors:

- Shoe Sorters: Shoe sorters are ideal for e-commerce operations that handle a high volume of small to medium-sized products. Using a series of shoes or diverters, they sort products into different chutes or bins based on predetermined criteria such as size, shape and weight.

- Cross Belt Sorters: Cross belt sorters work best for e-commerce operations that handle larger and heavier products. They use a series of cross belts to transport products to the appropriate destination chute or bin based on barcode scanning or other criteria.

- Tilt Tray Sorters: Tilt tray sorters are versatile and can handle a wide range of products in various sizes. Trays tilt to direct products to the appropriate chute or bin based on predetermined criteria.

- Pusher Sorters: Pusher sorters are suitable for e-commerce operations that handle a high volume of lightweight products. They use a series of pushers to direct products to the appropriate chute or bin based on predetermined criteria.

- Spiral Sorters: Spiral sorters are ideal for e-commerce operations that require a compact sorting solution. Spiral conveyors transport products to different levels and chutes based on the criteria you set.

Trust Span Tech for Your E-Commerce Automation Solutions

For e-commerce systems and conveyors that will boost your e-commerce warehouse operations, look no further than Span Tech. We have experienced teams that understand the fast-paced e-commerce market better than any other conveyor manufacturer and supplier. Our experience allows us to provide the equipment you need to ensure safe, accurate and timely e-commerce fulfillment.

Contact us to discuss your e-commerce automation needs and discover how we can help your business grow.