by Seth Bailey | Jan 29, 2018 | Industry Tips, Span Tech News

2017 was a tremendous year for Span Tech, and we are anticipating similar results for 2018. We are expecting exponential growth that will allow us to create even more innovative new products and solutions. Also we are planning on implementing training programs that...

by Seth Bailey | Jan 24, 2018 | Conveyors & Conveyor Parts, Industry Tips, Sorting & Merging

Transpositors provide right-angle product transfers and allow product lanes or patterns to be built across the width of receiving conveyors. The transfer function uses our sprocket driven MicroSpan Chain. Servo, pneumatic actuator or AC motor can power the depositing...

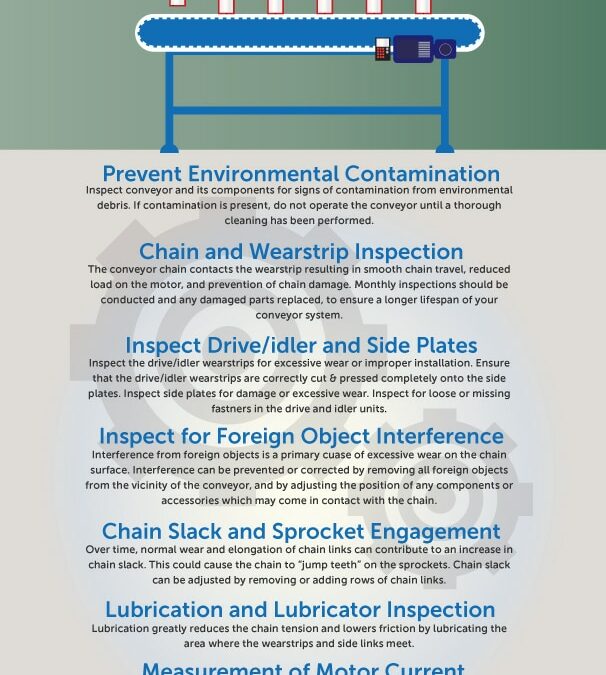

by Seth Bailey | Jan 16, 2018 | Industry Tips

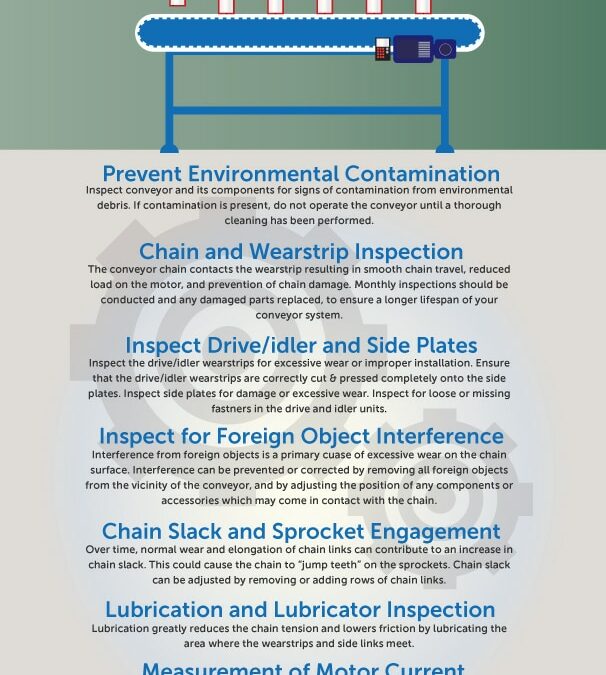

Your Conveyors are one of the most important pieces of equipment you can have. Without them running properly and efficiently you run the risk of slowing down and jeopardizing the entire production process. Each conveyor system should be inspected regularly, and the...