by Seth Bailey | Jul 26, 2018 | Conveyors & Conveyor Parts

Packaging conveyors are a must for transporting items quickly and efficiently. That’s why having a custom conveyor precisely for your needs is crucial to ensuring your products remain organized and undamaged. Let’s explore a few features that will help...

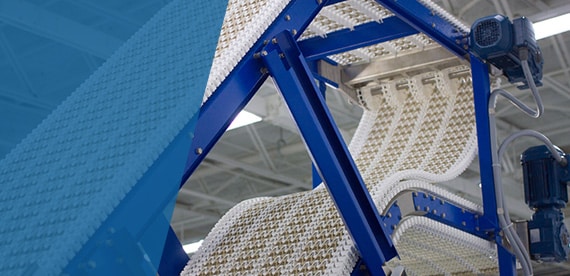

by Seth Bailey | Jul 25, 2018 | Changing Elevation, Conveyors & Conveyor Parts, Industry Tips

Efficiency of your packaging and distribution facility decreasing? Have you considered a Topper Lift? The Changing-Elevation Topper Lift from Span Tech is able to tackle tricky angles, elevation changes and product orientation changes without a programmable logic...