by Seth Bailey | Aug 21, 2018 | Conveyors & Conveyor Parts

As a distribution facility, you need your processes to run seamlessly so that each product arrives at its destination without trouble. You also want to make the most of your space. To achieve all this, you need a custom conveyor system that can handle tight turns and...

by Seth Bailey | Aug 13, 2018 | Chain Types, Conveyors & Conveyor Parts

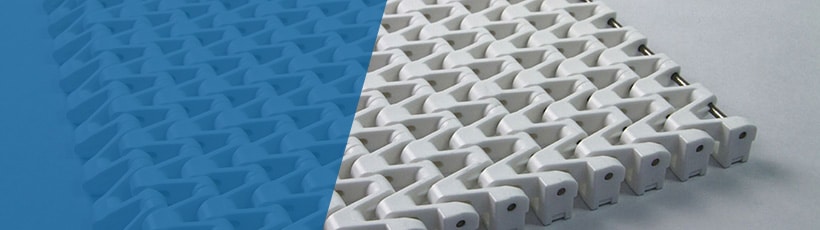

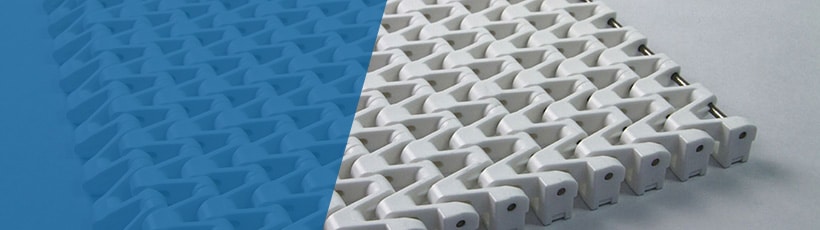

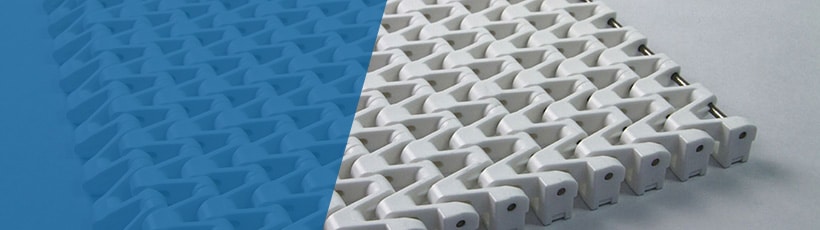

When purchasing your new modular, rebuildable and durable conveyors from Span Tech, you have a lot of options. Our patented plastic conveyor chain designs provide solutions applicable to a wide variety of products and industries. But which type is right for your...