History of Food Conveyor Systems

Conveyors were first used in the late 1700s to move freight onto ships at port. Originally operated with hand cranks, these early conveyors quickly morphed, and within a few years, they were powered by steam engines. Mechanically powered conveyors spread to other industries over the next 100 years and were eventually adopted by the food processing industry.

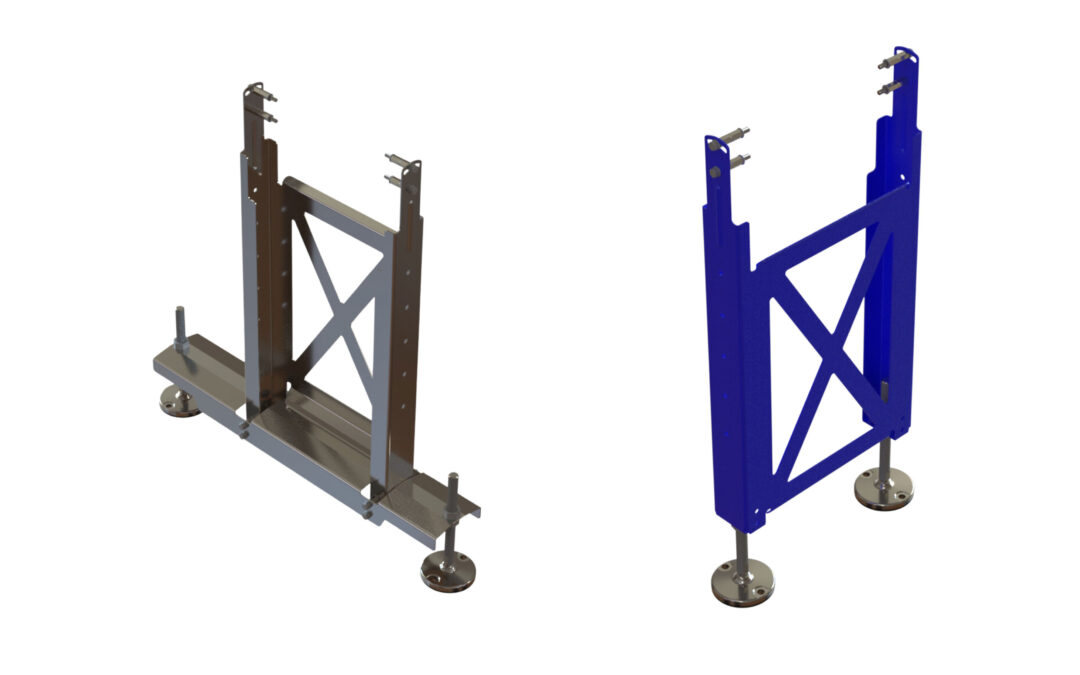

Regardless of the application, all conveyors share many of the same components:

- A motor controller

- A power mechanism that manages conveyor speed

- The conveyor’s support structure

- A belt, tray, screw or other means of conveying the material

As food production became more industrialized, manufacturers quickly realized the advantages of food conveyor systems. Operations no longer needed to wait on workers to move heavy loads to different factory locations, creating important production efficiencies. The introduction of the food conveyor belt also helped the food industry meet increasing state and federal regulations — conditions became more sanitary as food was handled less.

Manufacturers use food conveyor systems to move:

- Raw materials from storage to the processing area

- Finished products onto the packaging line

- Packaged goods to the shipping area

Benefits of Food Handling Conveyors

Increased automation in the form of food conveyor systems brought benefits to the food industry that extend well beyond improved sanitation. Food manufacturers that installed conveyors realized a wide range of advantages. Some of the main benefits include:

1. Higher Production Rates

As in any industry, automation increases productivity. In the case of the food industry, food handling conveyors allowed bulk foodstuffs to be moved more quickly so the operations could process more food in less time.

2. Better Worker Safety

With the adoption of food conveyor systems, workers no longer need to move heavy loads over long distances. This removes one of the prime causes of worker injuries.

3. Lower Labor Costs

More food handling conveyors mean fewer workers needed to complete the tasks. This reduces labor costs, including not only wages and benefits but also expenditures for recruitment, training and retention.

4. Fewer Errors

Because they’re automated, food conveyor systems will always transport the right products to the right place, reducing the chance of human error.

5. Improved Compliance With Quality Standards

The use of food-grade conveyors reduces the likelihood of contamination and breakage, allowing manufacturers to more easily maintain quality standards.

6. Increased Versatility

Both the speed and direction of material flow can be changed on food conveyor systems, making conveyors a versatile addition to food processing operations. Conveyors’ modular design also means they can be reconfigured to meet changing production requirements.

Food Conveyor Systems for Every Need

Customizable food handling conveyors can meet any requirement of the food industry. They can merge, accumulate, incline, decline, divide, vertically convey, deposit, reject and reclaim foodstuffs as needed. Specialty systems like washdown conveyors help food manufacturers meet sanitary regulations. Wire mesh belt conveyors are ideal for use around freezers, and wedge conveyors can be used for transferring the boxes used in food packaging.

Food Handling Conveyors That Meet Your Requirements

As a leader among food conveyor manufacturers, Span Tech has the expertise, knowledge and experience to design the food and beverage conveyor systems that are right for your application, whether your operation involves fruit, meat, vegetables, convenience foods, dairy, frozen foods, baked goods or more.

As we engineer your custom food conveyors systems, we take into account a wide range of design considerations, including the available space, the kind of food being transported, the required speed of movement and the height and distance the food must cover. Specifications can include drive location, throughput, rated speed, load capacity and frame configuration.

Contact us today for an estimate on the food handling conveyors that will overcome your toughest challenges.