In the world of food production, minimizing and preventing product damage, while maintaining the safety of your employees, and keeping your facility in top condition can be a Herculean task. Because of this, having conveyor systems with features that keep your facility safe, productive, clean and efficient is extremely important. Here at SpanTech, our food handling conveyors are designed to not only meet these needs but exceed them.

Keep reading to view our top five custom conveyor features for the food production industry and learn why you need them in your facility today.

Metal Detectors

It’s vital to keep metal contamination out of edible products. The best way to prevent any possible metal contamination is by utilizing a metal detector on your food handling conveyor.

At Span Tech, Our conveyors can be equipped with custom, state-of-the-art metal detectors. They offer reliable protection against contamination by ferrous and non-ferrous metals. Our metal detector-ready conveyors are best suited for applications in the food, pharmaceutical, and other industries.

Clean Out Holes

Cleanliness and the ability to clean efficiently are important aspects of keeping your food processing conveyors in tip-top shape. Clean out holes are commonly used in food production facilities that need to maintain a high level of cleanliness year-round.

Our washdown conveyor is commonly used for better access to the inside of the conveyor bed for a more effective and efficient washdown.

Pillow Top Chains

A top feature for food production companies when it comes to custom conveyor systems is the ability to handle the most delicate of products. This is where pillow top chain conveyors come into play. This custom conveyor belt add-on is perfect for food production facilities due to its ability to handle delicate food products with ease and precision.

SpanTech’s innovative pillow top chain virtually eliminates the need for a powered transfer unit and allows the conveyor to sit extremely close to the transfer unit. This results in the successful transfer of very small food products that could otherwise get caught or snagged in traditional transfers.

Sidewalls

Sidewalls for custom conveyor belts can sometimes be an overlooked aspect of food production. But it should never be underestimated. These sidewalls are an effective way to both ensure sanitation and guard against the moving sides of the conveyor chain. They also function as a guide for products on a food processing conveyor belt.

Our add-on sidewalls are the perfect safety component for not only your products but your employees. SpanTech sidewalls create a low amount of friction. Sidewalls are available for a custom design or fitting to individual applications.

Drip Trays

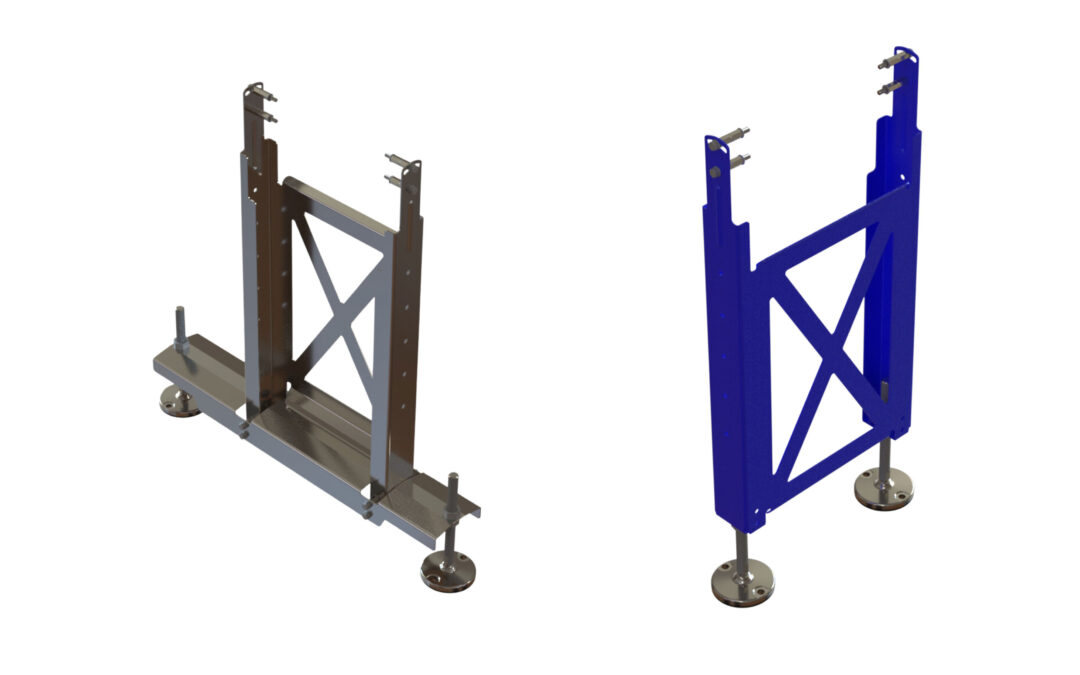

In a food production facility, liquid and debris can easily fall off of a conveyor. Drip trays are designed to catch liquid and debris and prevent a potential safety hazard or any damage to the product.

SpanTech’s drip trays are custom designed for each individual custom conveyor. Available in stainless steel, drip trays can be equipped with drain plugs so liquids can be routed into a centralized drainage system.

Get A Totally Custom Conveyor System Today

All of SpanTech’s conveyor systems and add-ons are completely customizable to fit your specific needs. Have a question or need more information? Contact us today.