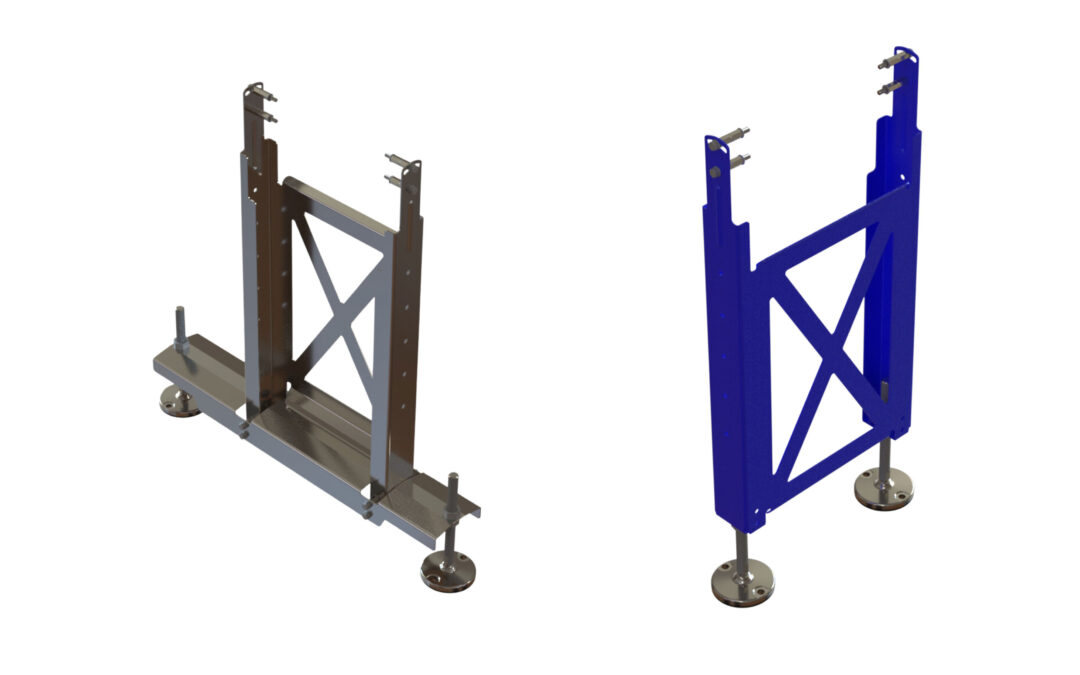

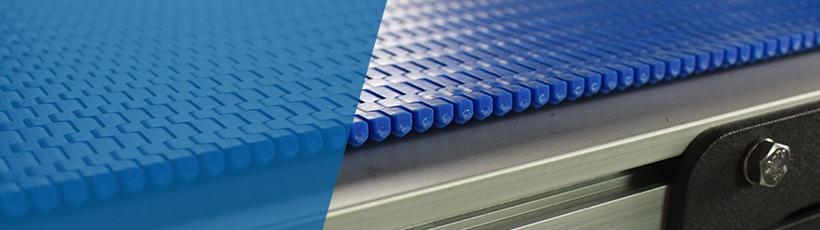

Span Tech has announced its newest line of durably designed power “belt” conveyors, a more efficient alternative to traditional conveyor systems. The new EZSpan plastic belt conveyor can benefit a wide array of industries, including pharmaceutical, cosmetic, e-commerce, packaging distribution, plus many more.

The EZSpan tabletop conveyor system utilizes extremely thin, modular plastic chains, offering several advantages over typical belt conveyors. For one thing, the new flat belt conveyor system from Span Tech virtually eliminates any possible tracking issues that are considered “the norm” with traditional belt conveyors. Plus, the thin conveyors are built to fit perfectly between machines without the worry of the take-up unit creating a large gap or interfering with the machine. And that’s just the beginning.

What Makes EZSpan Belt Conveyors Unique

- No need for tracking components. Thanks to the self-centering MicroSpan chain in place of a traditional belt, there’s no need for tracking components (like crowned rollers or adjustment screws) that require constant monitoring. And the take-up unit’s new automatic “tension detector” alerts you if there is too much chain stretch in the system.

- Hassle-Free Maintenance. Rather than using a splice kit or ordering an entirely new belt, EZSpan offers the ability to quickly and easily replace links when needed. The conveyor drive unit has also been designed for increased performance and to make maintenance easier than ever, with most components accessible simply by removing a few pins.

- Constant end-to-end distance. There are no take-up units at the ends of the conveyor, meaning the length you order is the length you get — and the length it stays. Choose any length from 2.4 feet up to 30 feet.

- No integration problems. The EZSpan is the thinnest belt conveyor on the market, with a profile height of only 1.5 inches. This makes the power belt conveyor easy to integrate into your existing machinery.

How EZSpan Belt Conveyors Can Boost Efficiency

- Less equipment needed. No gaps between machinery means no need to buy equipment to fill them.

- Better use of human resources. Since employees won’t have to monitor the EZSpan like they would standard belt conveyors, they can spend their time more productively.

- Reduced downtime. Simpler maintenance means more time in operation.

- Cost savings. EZSpan’s space-saving design equates to long-term cost savings.

A Complete Power Belt Conveyor System

A variable frequency drive is also included with the EZSpan belt conveyor, and all components have been designed for increased performance and durability, and easy maintenance.

Optional low-profile nose bar, adjustable guide rail, and supports and casters are also available.

Tested And Proven

The EZSpan belt conveyor design has been extensively tested to ensure it meets or exceeds demands. Time after time and test after test, it’s proven to be a more practical alternative to traditional belt conveyors — and wiser business investment.

Get your own EZSpan belt conveyor system to make the most of your operation’s time and money. Start here for a quote.