GMP Meaning

If you’re in the pharmaceutical industry, odds are you’ve heard the acronym “GMP” before. But do you know what it means? GMP stands for good manufacturing practices. It’s a term used interchangeably with CGMP, which means current good manufacturing practices. The Food and Drug Administration (FDA) uses these practices to regulate and ensure pharmaceutical quality, as well as quality in other industries like cosmetics and food production.

Why is GMP Important in the Pharmaceutical Industry?

From monitoring proper design to controlling facility processes, good manufacturing practices are an essential part of the pharmaceutical industry. CGMP regulations require medicine manufacturers to adequately control their operations. By following these regulations, pharmaceutical companies ensure the drug products’ identity, strength, quality and purity.

When your pharmaceutical company follows these practices, you can avoid many of the most common causes of quality failure like drug contamination, deviations or mix-ups. Consumers typically can’t detect that a drug is safe or if it will work, so it’s crucial to manufacturing pharmaceutical products under the conditions and practices mandated by CGMP. Continue reading to discover some of the best manufacturing practices to follow to assure the safety and efficacy of your pharmaceutical products.

Proper Research & Development

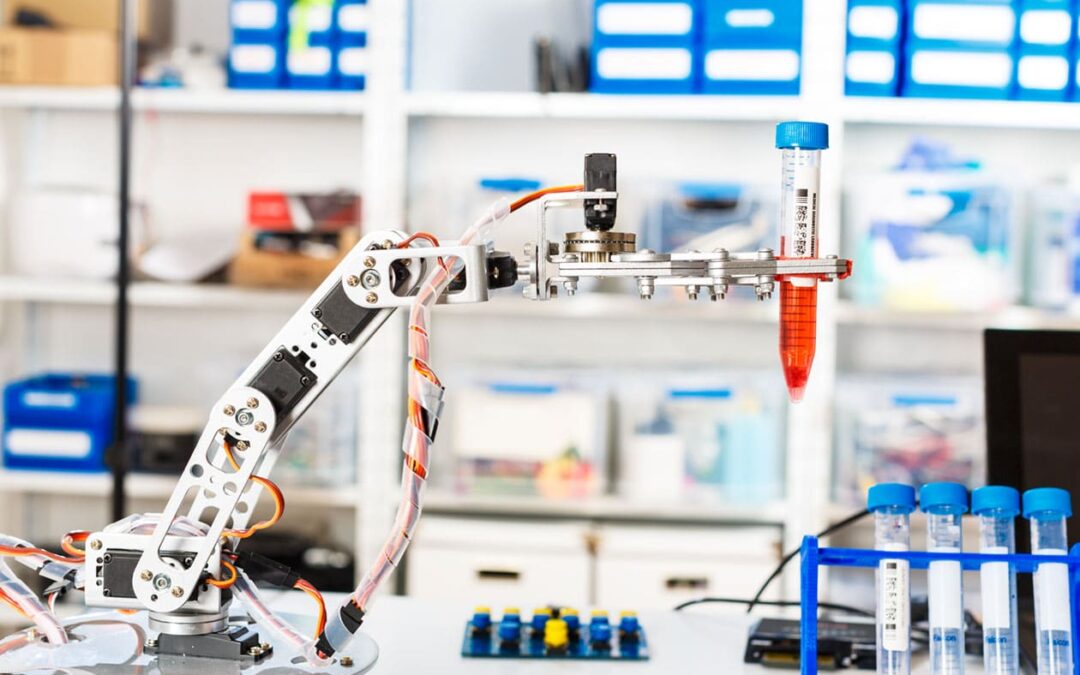

In the pharmaceutical industry, extensive research and development are incredibly important. Good manufacturing practices mandate that scientists conduct thorough studies to determine which drugs to develop. Thousands of tests must take place in labs to conclude if the drugs will work.

All drugs must undergo a clinical trial. Results from trials and testing are used for further development. This helps ensure top pharmaceutical quality.

Pharmaceutical Quality Assurance & Control

Quality assurance and control play a major role in good manufacturing practices. They ensure that the necessary and relevant tests are carried out and pharmaceutical products aren’t released until deemed satisfactory. Pharmaceutical quality and assurance can be achieved through tactics such as:

- Conducting monitored testing and sampling

- Setting strict rules and specifications for all employees to follow

- Keeping tools and ingredients as organized as possible

- Documenting and recording procedures

Detailed Analysis of Manufacturing Processes

For ultimate quality and reliability, the manufacturing process for pharmaceutical products must be consistent and repeatable. Even the slightest change in a drug’s composition can have life-threatening effects on users.

To help avoid risk, your organization must analyze its manufacturing process and define strict, cohesive methods to follow. In doing this, you’ll ensure that every product is made in accordance within predefined specifications and that each batch is consistent and safe to administer.

If any changes occur when creating the product, it should be analyzed closely and checked for pharmaceutical quality. Any products losing quality as a result of these alterations are classified as contaminated and should be discarded.

Complete Inventory Visibility

The way your team stores and transports products to different channels is important. Complete downstream inventory visibility will help you implement good manufacturing practices like:

- Saving time when compiling shipments

- Monitoring inventory levels

- Prioritizing safety measures

- Continuously improving the supply chain

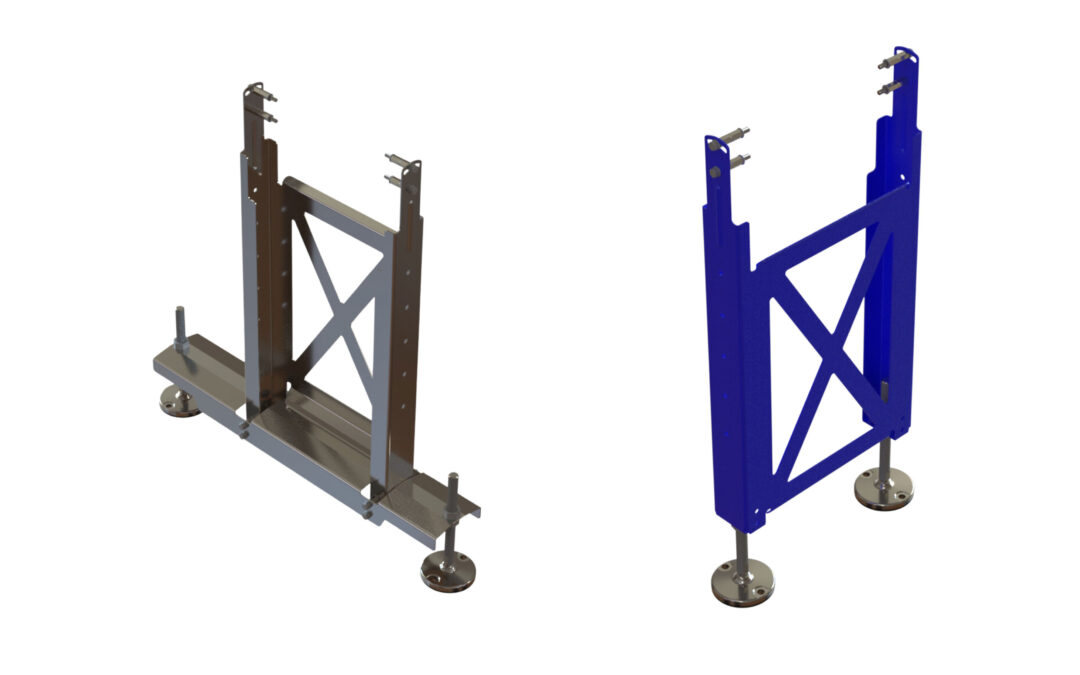

Premium Equipment

Success in the pharmaceutical industry is impossible without proper manufacturing tools and equipment. Along with selecting the right warehouse, you need machinery designed for effective cleaning and the prevention of cross-contamination. Having the proper equipment will also help you safely transport items like vials, bottles, bags, tubes, small cartons and more. In compliance with CGMP, each piece of machinery must be validated and calibrated and have procedures, schedules and records.

Implement Good Manufacturing Practices with Custom Conveyors from Span Tech

Span Tech is no stranger to manufacturing in the pharmaceutical industry. Since 1988, we’ve been bringing you, premium-quality pharmaceutical conveyors, for manufacturers and distributors. Our conveyor solutions feature:

- High-speed palletizing

- Break pack picking using in-voice and RF picking technology

- Solutions for tracking and logging all movement

- High-speed sortation systems

We’re proud to bring you the best possible products to help you implement good manufacturing practices and ensure pharmaceutical quality. Reach out to our staff today to learn about our custom conveyors and start your estimate!