BLOG

Case Studies

SEE HOW OUR CLIENTS BOOST THEIR BOTTOM LINE WITH THE WORLDS MOST RELIABLE CONVEYOR SYSTEMS

Explore real-world applications of Span Tech’s products in action. Our case studies highlight how we solve unique challenges across various industries.

J. W. Allen Case Study

J. W. Allen Case StudyThe Perfect Partners: Rich\'s Products Corporation & Span Tech Span Tech\'s Customer Service Manager decided to visit Rich Food Corporation\'s Tennessee facility to inspect the wear on some of the Span Tech conveyors that had been in use there since 1994. He was surprised by what…

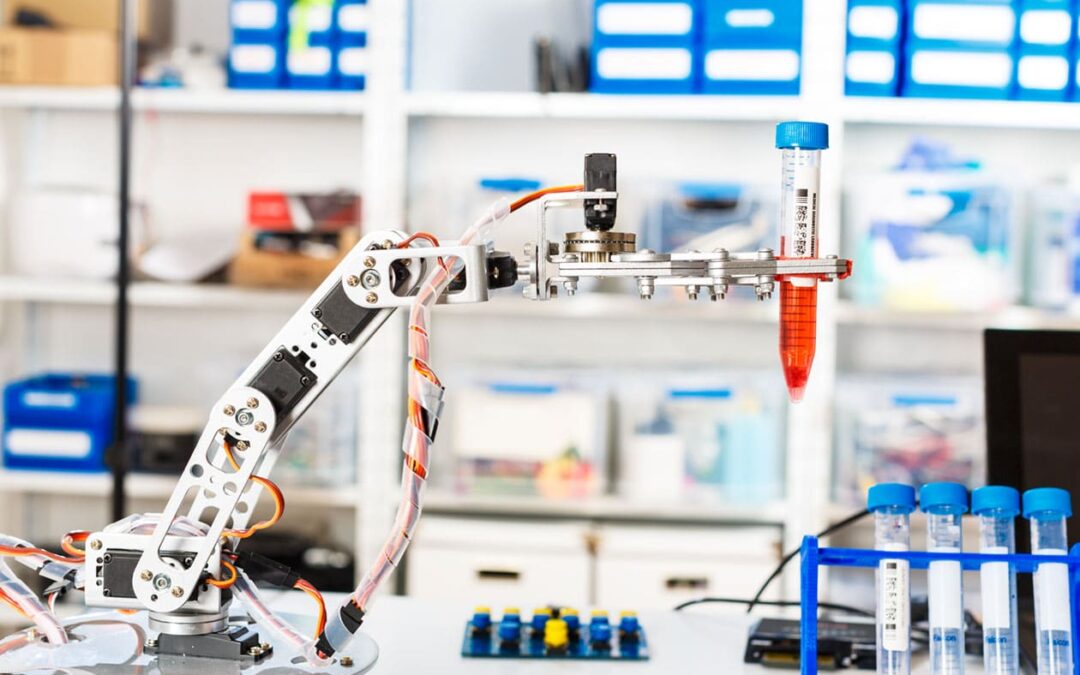

COBE BCT Case Study

COBE BCT Case StudySmall Parts Medical Manufacturer Optimizes Production Slow production rates and ergonomic problems were impacting the morale of COBE BCT\'s employees. The medical manufacturing company needed an innovative production line to streamline their process, but the highly technical nature of their work made finding a partner difficult. Enter…

Fleischer’s Bagels Case Study

Fleischer’s Bagels Case StudyFleischer\'s Growth Aided by Custom Designed Conveyor System As national demand for Fleischer\'s Bagels and their various products increased, so did the company\'s need for high volume, smoothly-automated production. Finding a universal yet intuitive solution seemed unlikely and expensive. Fortunately, it was Span Tech they called on…

Mr. Coffee Conveyor Case Study

Mr. Coffee Conveyor Case StudyThe workers at Mr. Coffee\'s Ohio-based plant were facing serious efficiency issues caused by the company\'s outdated plastic conveyors. Chains and sprockets needed frequent replacement. The whole cumbersome system had to be serviced regularly and the plastic couldn\'t cool quickly enough, and so on.Coffee filters produced…

ODOM’s Tennessee Pride

Tennessee Pride Case StudyRamping up Sausage Production With limited floor space in their primary plant, Tennessee Pride (one of the nation\'s largest private sausage makers) needed a custom-tailored material handling solution. Span Tech\'s Designer System® conveyor line delivered such great results that Span Tech would soon become the sole supplier…

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.