CONVEYOR DRIVES

HOLLOW SHAFT MOUNT

Easy to maintain, service or replace, our popular Hollow Shaft Mount conveyor drives are reliable and keep operations running smoothly and on time.

A typical Span Tech conveyor is powered by an SEW-Eurodrive helical-worm gearmotor, with a hollow-shaft mount. This design facilitates easy maintenance, and simplifies removal/replacement if necessary. The gearmotor’s hollow shaft is keyed to one end of the conveyor’s drive shaft, while a torque arm bracket secures the motor to the conveyor frame.

Videos

Features & Benefits

Powered by an SEW-Eurodrive helical-worm gearmotor, with a hollow-shaft mount

Facilitates easy maintenance

Simplifies removal/replacement if necessary

Gallery

Downloads

Applications

Industries

Why Choose Span Tech for Spiral Conveyors

Customizable

SpanTech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Designed for continuous use in demanding environments, SpanTech’s conveyors maintain efficiency and reduce downtime, with low-friction operation leading to less wear and tear.

Partnership

SpanTech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

By choosing SpanTech, businesses invest in a partnership that prioritizes innovation, quality, and customer satisfaction, offering a superior solution for their spiral conveyor needs.

Conveyor Articles

Conveyor Belt History: The Backbone of Modern Manufacturing

Overview The industrial conveyor belt is one of manufacturing’s most critical yet often overlooked innovations, seamlessly powering modern production lines across nearly every industry. From…

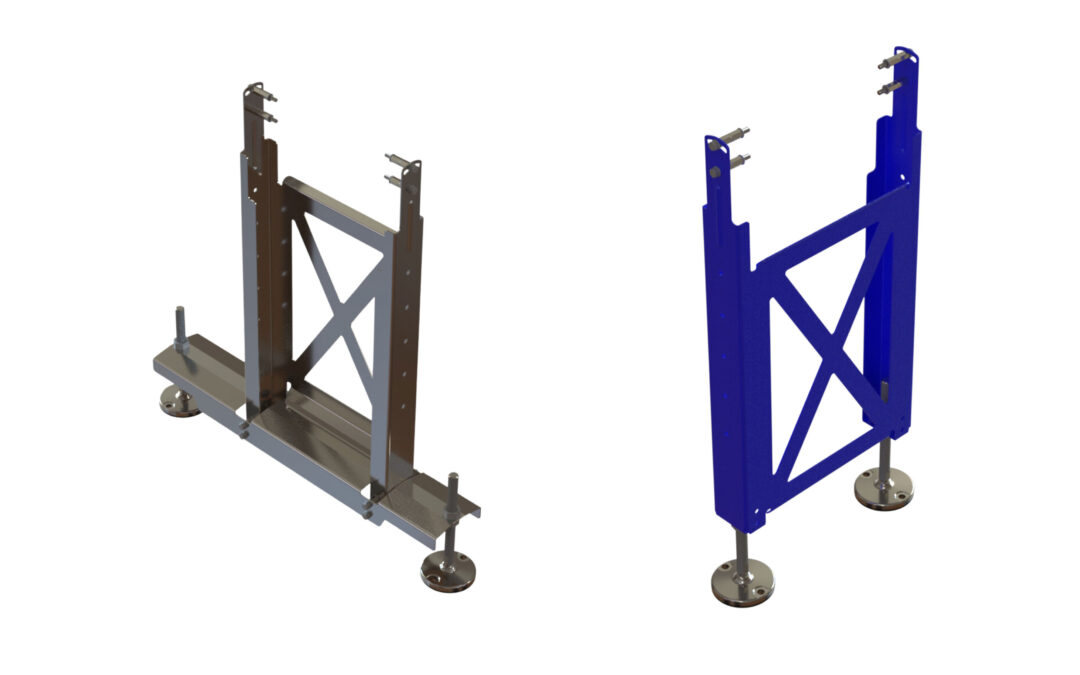

Span Tech Reinvents Conveyor Support Systems with New Sheet Metal Supports

FOR IMMEDIATE RELEASE Span Tech Reinvents Conveyor Support Systems with New Sheet Metal Supports Innovative Design Enhances Cost Efficiency and Sanitation for Modern Manufacturing Glasgow,…

Visit Span Tech at Pack Expo 2025

Visit Span Tech at PACK EXPO 2025 – Discover the Future of Conveyor Technology PACK EXPO 2025 is the premier event for packaging and processing…

Visit Span Tech at ProMat 2025 – See Our Latest Conveyor Innovations!

ProMat 2025 is the leading event for supply chain, manufacturing, and logistics professionals, and Span Tech is thrilled to be part of it! Taking place…

Why Traditional Conveyor Supports Are Holding You Back

Is Your Conveyor Support System Costing You More Than You Think? Conveyor systems are the backbone of efficient production, but one often-overlooked component may be…

A Look Into the Accumulating Conveyor Applications Shaping Industries

Overview Accumulating conveyor applications are fundamental in today’s manufacturing environment, where efficiency and productivity are high priorities. These conveyors facilitate smooth product flow through different…

J. W. Allen Case Study

J. W. Allen Case StudyThe Perfect Partners: Rich\'s Products Corporation & Span Tech Span Tech\'s Customer Service Manager decided to visit Rich Food Corporation\'s Tennessee…

COBE BCT Case Study

COBE BCT Case StudySmall Parts Medical Manufacturer Optimizes Production Slow production rates and ergonomic problems were impacting the morale of COBE BCT\'s employees. The medical…

Fleischer’s Bagels Case Study

Fleischer’s Bagels Case StudyFleischer\'s Growth Aided by Custom Designed Conveyor System As national demand for Fleischer\'s Bagels and their various products increased, so did the…

Mr. Coffee Conveyor Case Study

Mr. Coffee Conveyor Case StudyThe workers at Mr. Coffee\'s Ohio-based plant were facing serious efficiency issues caused by the company\'s outdated plastic conveyors. Chains and…

FAQ’s About Conveyor accessories

Are Spiral Conveyors Customizable for Specific Industry Needs?

Yes, spiral conveyors are highly customizable. They can be tailored to meet specific operational requirements, including varying belt widths, speeds, and materials. This flexibility allows them to be adapted for different types of products and operational needs, ensuring that they fit seamlessly into existing systems and processes.

What Are the Maintenance Requirements for Spiral Conveyors?

Spiral conveyors are designed for durability and low maintenance. They typically require less upkeep due to their efficient design and fewer moving parts compared to traditional conveyors. However, regular inspections and routine maintenance are recommended to ensure optimal performance and longevity. This may include checking and adjusting belt tension, lubricating bearings, and inspecting worn parts.

Can Spiral Conveyors Be Integrated With Existing Conveyor Systems?

Absolutely. Spiral conveyors can be seamlessly integrated with existing conveyor systems. Their modular design allows for easy incorporation into current material handling setups. This integration capability ensures that spiral conveyors can enhance existing workflows without the need for extensive modifications or overhauls of current systems.

![]()

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

![]()

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

![]()

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.