What Makes Spiral Conveyors So Effective?

Spiral conveyors are engineered for vertical product movement in compact footprints. Compared to traditional incline or elevator systems, they save floor space, maintain product orientation, and enable continuous flow between production levels.

Span Tech’s spiral conveyor systems are chain-driven and highly modular, making them ideal for applications ranging from food and beverage to e-commerce and industrial packaging. Their design ensures gentle handling and consistent performance, even in high-speed environments.

Key Factors to Consider When Buying a Spiral Conveyor

Selecting the best spiral conveyor starts with a clear understanding of your operational requirements. Spiral conveyors vary widely in design, materials, and capabilities. The right choice will depend on factors such as your product type, production volume, facility layout, and long-term maintenance expectations. A misaligned conveyor can cause bottlenecks, increased downtime, and unnecessary costs, so taking time to evaluate key features upfront is essential for long-term success.

1. Load Capacity & Product Specifications

Understand your heaviest products and overall throughput needs. These details determine the chain strength, motor size, and structural support your system requires. Underrated components can lead to wear and operational failures, while overspecifying adds unnecessary cost.

2. Space Constraints & Layout Compatibility

Spiral conveyors are built for space savings, but the diameter of the spiral, infeed and outfeed elevations, and turning radius must align with your facility’s layout. Systems like the Outrunner Spiral are designed for flexible configurations and tight integration.

3. Speed & Throughput Requirements

Speed matters, especially when coordinating with upstream and downstream processes. Select a system that supports variable speeds or VFD control if your production rates fluctuate throughout the day.

4. Maintenance & Durability

Look for systems with long-wear components, easy access points, and minimal lubrication needs. Many of the best industrial spiral conveyors feature enclosed gear drives, self-lubricating chains, and accessible chain pathways that reduce maintenance demands.

5. System Integration & Customization

Your spiral conveyor should fit seamlessly into your broader system. Key customizations include chain surface texture, directional orientation, finish material (e.g., stainless steel for washdowns), and entry/exit placement. These features ensure optimal performance without costly modifications to your existing layout.

Spiral Conveyor Design Calculations: Why They Matter

Proper spiral conveyor design calculation is the foundation of any reliable system. Variables such as conveyor pitch, elevation change, load torque, and chain tension all factor into the overall performance and longevity of the system. Trusted spiral conveyor manufacturers like Span Tech use advanced modeling to validate each design before it’s built, helping you avoid unplanned breakdowns or costly inefficiencies.

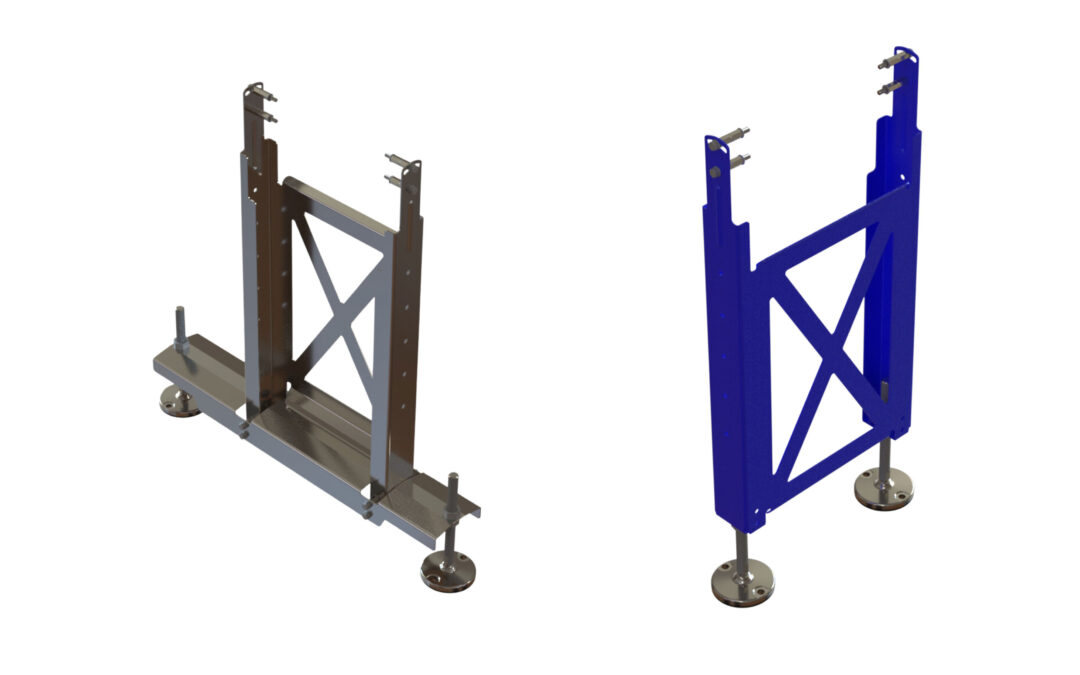

Comparing Spiral Conveyor Models: Original vs. Spiral 2.0

Span Tech offers two high-performance spiral conveyor models, each with its own set of advantages. Understanding how they compare will help you select the best fit for your operation.

Original Spiral

- Proven design used across industries for more than a decade

- Robust construction ideal for consistent, heavy-duty applications

- Flexible configuration for custom layouts and diverse product types

Spiral 2.0

- Improved installation efficiency with simplified components and faster setup

- Reduced maintenance needs thanks to optimized chain engagement

- Quieter operation for noise-sensitive environments

- Greater vertical stability, making it ideal for tall spirals or high-speed applications

Explore our in-depth Original Spiral vs. Spiral 2.0 comparison to determine which model is the best spiral conveyor for your specific production goals.

Spiral 2.0 Conveyor – High-Performance Vertical Transport with a Smaller Footprint

Maximize efficiency and save floor space with Span Tech’s Spiral 2.0 Conveyor, the next evolution in vertical product handling. Designed for high-speed, high-volume applications, Spiral 2.0 offers a compact, smooth, and reliable way to move products between different levels without the need for complicated transfers or large incline conveyors.

FAQs About Spiral Conveyors

Choosing a spiral conveyor is often a long-term investment, and buyers naturally have questions before making a decision. Below are answers to some of the most common questions we hear from businesses looking to install or upgrade their conveyor systems.

How do I determine the right load capacity for my spiral conveyor system?

Analyze your heaviest product and desired throughput. Accurate load calculations will inform chain type, gear motor strength, and structural requirements. Most manufacturers, including Span Tech, offer load testing and design services during the quoting phase.

How do I ensure the spiral conveyor system I choose integrates well with my existing equipment?

Review your current line layout, including infeed/outfeed elevations, flow direction, and required timing. A modular conveyor like the Outrunner Spiral offers flexibility in design, making it easier to slot into existing systems with minimal disruption.

What is the typical lifespan of a spiral conveyor system, and what can impact its longevity?

With proper installation and maintenance, a high-quality spiral conveyor can last 10 to 20 years. Factors such as operating environment (wet, dusty, hot), load cycles, and maintenance frequency all influence longevity.

Ready to Configure Your Spiral Conveyor?

Selecting the best spiral conveyor system is one of the most impactful decisions you can make when optimizing material flow and vertical integration. Whether you’re addressing layout constraints or preparing for increased capacity, Span Tech’s spiral conveyors deliver proven results with long-term reliability.

Speak to an applications engineer today for a custom recommendation tailored to your workflow, facility size, and operational goals.