1. Maximizes Vertical Space in Crowded Facilities

One of the biggest benefits of spiral conveyors is their ability to move products vertically without

consuming excessive floor space. Traditional conveyor systems require long horizontal runs to achieve

even modest elevation changes. Spiral conveyor designs, however, condense that motion into a compact

footprint, freeing up valuable space for storage, work cells, or staging areas. This makes them ideal

for warehouses where square footage is at a premium.

2. Eliminates Chokepoints in Multi-Level Transfers

Traditional incline conveyors often struggle with elevation changes in tight spaces. A spiral conveyor

belt system provides a continuous and controlled path between floors, eliminating the stop-start delays

that can occur at manual transfer points or lift zones. By enabling smooth vertical transport, spiral

conveyors help facilities avoid congestion around elevators or loading stations, keeping product

movement consistent and predictable.

3. Improves Product Flow and Line Balancing

Spiral conveyors for warehouses are especially effective in maintaining consistent flow between

processing stations. As products move between different levels or stages of production, these conveyors

ensure items arrive at the right pace to avoid pile-ups or starvation. This steady flow supports better

line balancing, reduces idle time, and increases overall throughput, critical advantages in high-demand

environments.

4. Reduces Manual Handling and Labor Requirements

The streamlined movement enabled by spiral conveyor belts minimizes the need for human intervention. This

reduces labor costs, but also limits safety risks and delays caused by manual sorting or lifting, common

culprits behind warehouse bottlenecks. By automating vertical product movement, spiral conveyors free up

staff to focus on more value-added tasks, improving labor efficiency without compromising performance.

Learn More: 3 Signs Your Warehouse Could

Benefit from a Spiral Elevator Conveyor

5. Speeds Up Order Fulfillment in E-Commerce Operations

In fast-paced fulfillment centers, delays in vertical movement can result in slow picking and packing

times. Spiral conveyors offer fast, consistent, and automated product transport—critical for same-day or

next-day shipping expectations. Their ability to connect mezzanines, sortation areas, and packaging

stations makes them a key asset in e-commerce distribution networks that demand speed, accuracy, and

flexibility.

6. Adapts to Tight or Irregular Layouts

Because spiral conveyor designs are modular and compact, they fit easily into unconventional spaces. This

flexibility allows them to be configured around existing equipment or architectural constraints—making

them a go-to solution in retrofit applications and space-constrained zones. Whether the challenge is low

ceilings, narrow aisles, or awkward angles, spiral conveyors can be tailored to meet the needs of your

unique layout.

7. Supports High Throughput with Low Maintenance

Unlike vertical lifts or complex transfer systems, spiral conveyors have fewer moving parts and lower

maintenance demands. Their robust design ensures consistent operation, which translates to less downtime

and more predictable performance, a key factor in long-term warehouse bottleneck solutions. With proper

upkeep, they can deliver years of reliable service, reducing unplanned outages and maintenance-related

disruptions.

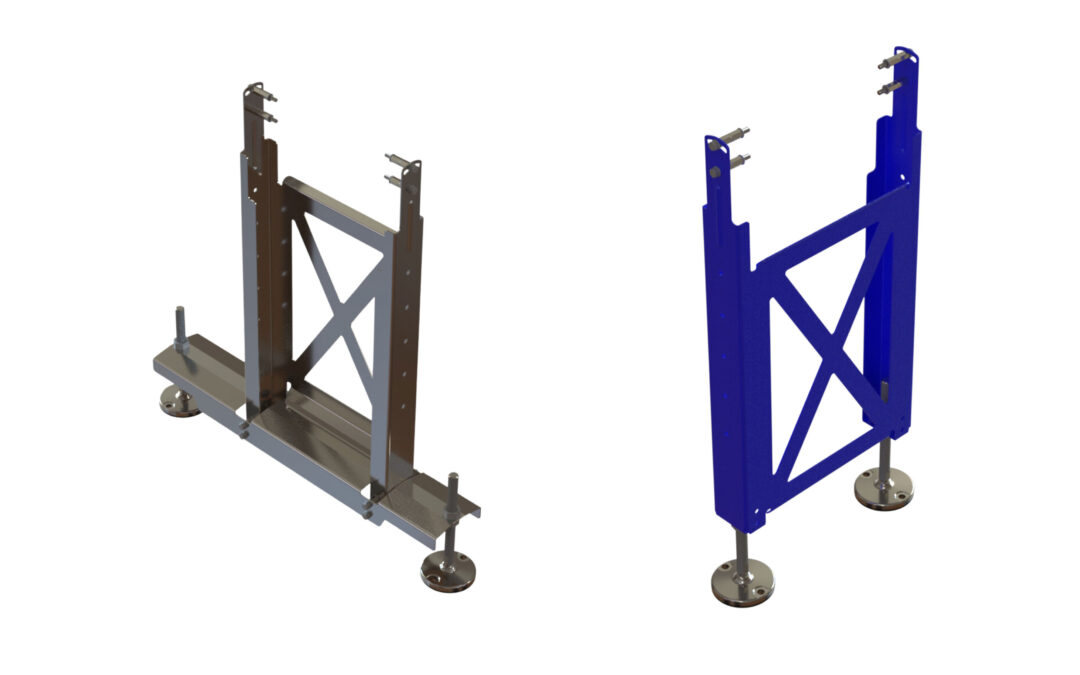

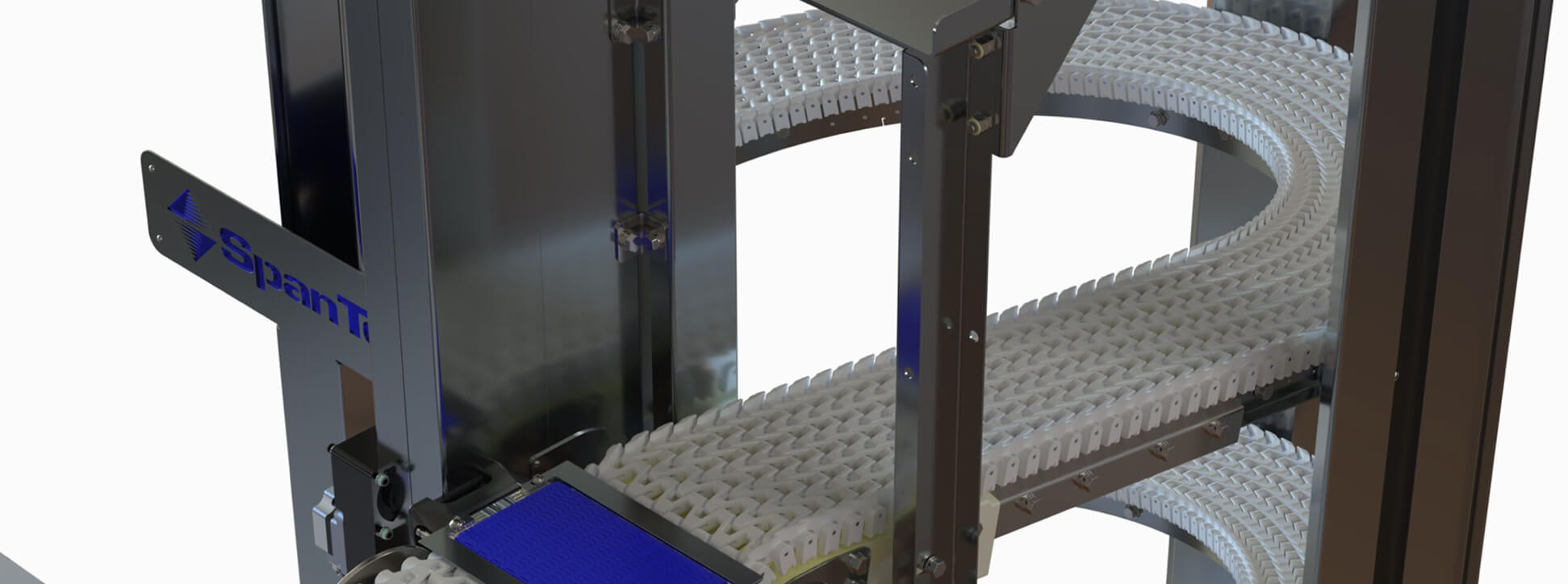

Spiral 2.0 Conveyor – High-Performance Vertical Transport with a Smaller Footprint

Maximize efficiency and save floor space with Span Tech’s Spiral 2.0 Conveyor, the next evolution in

vertical product handling. Designed for high-speed, high-volume applications, Spiral 2.0 offers a

compact, smooth, and reliable way to move products between different levels without the need for

complicated transfers or large incline conveyors.

FAQs About Spiral Conveyors

Spiral conveyors often raise questions about how they integrate into different warehouse environments. Below are

common FAQs from decision-makers looking to improve operations with this proven technology.

What types of warehouse layouts benefit most from spiral conveyors?

Spiral conveyors work well in multi-level or space-constrained facilities where vertical product movement

is required without interrupting floor-level workflows. They’re ideal for e-commerce fulfillment, cold

storage, food production, and manufacturing environments.

Are spiral conveyors customizable to fit specific warehouse needs?

Yes, Span Tech spiral conveyors are fully customizable in terms of height, direction, chain type, and

incline angle. This flexibility makes it easy to tailor each unit to your unique space and application

requirements.

What is the typical lifespan of a spiral conveyor system, and how does this affect ROI?

With proper maintenance, a spiral conveyor system can last 10-15 years or more. Their long service life,

combined with low energy use and reduced maintenance needs, supports a strong return on investment for

most facilities.

Solve Warehouse Bottlenecks with

Spiral Conveyor Design

Span Tech’s spiral conveyors are engineered to streamline product movement,

improve efficiency, and reduce congestion, no matter how complex your layout. If you’re ready to

optimize your facility with a smarter vertical transport solution, contact our team today or

explore our spiral conveyor systems to find the right fit for your operation.