Whether you have a factory, warehouse, distribution center or packaging facility, choosing the best conveyors for your workflow can make all the difference in your efficiency. And purchasing a conveyor that meets all of your needs is much easier when you’ve identified your goals and developed a system.

For a truly successful and efficient operation, you first need to ask yourself a few questions:

- What are you processing or packaging?

- Are you going to be processing or packaging one item or multiple items?

- How are items being introduced to the system and at what rate?

- How does this relate to the packing and/or processing rate?

- How many orders or items need to be shipped in a week? In a day?

- Do you have a peak season when output requirements ramp up?

- What are the requirements for the most demanding part of each day?

- What is the layout of your warehouse, distribution center or other facilities?

If you already know or have now determined the extent of your conveying needs, you’ll have a better idea of what to look for when shopping for a conveying system. And by presenting the various types of conveyor systems and products in categories based on your logistical goals, we hope you’ll have an even clearer idea of which are the best conveyors for your business. The following are some common conveying requirements and a few coordinating Span Tech products that can help.

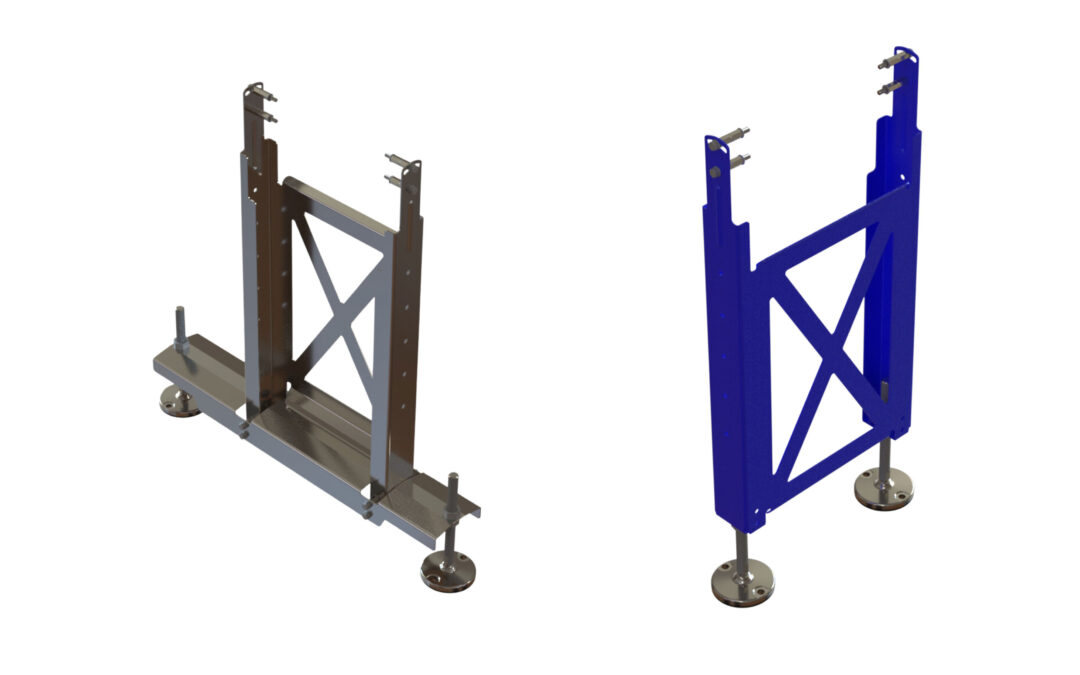

Transferring Materials

One of the more common needs in a warehouse or distribution center is the ability to move products in a linear manner from one conveyor to the next. Span Tech’s transfers are strong enough for heavy products while remaining smooth enough for the smallest and most delicate of products. Our proven technology was developed to work seamlessly with our conveyors but can easily be adapted for use with other systems. To make sure you have the best conveyors for any job, we offer many types of transfer conveyors. The following are a couple of ones we highly recommend.

Gravity Transfer

Recommended for e-commerce, packaging and distribution industries, Gravity Roller Transfers are ideal for non-powered transfer applications. The transfer roller design was created with integration in mind. This is why it can be placed as close as possible to other machinery, making for a smooth and seamless transport. And the roller’s small nose bar conveys even the smallest of products safely and securely.

MicroSpan Transfer

When you need a powered transfer, this product can make your end-to-end product movement easier than ever. The MicroSpan Transfer is a compact and durable transfer solution that was made to last. These compact transfers have the ability to be slave-driven from the main conveyor shaft or independently powered by their own gear motors. And with variable angle capability, it can be used for declines with “feed off” applications or for inclines with “feed on” applications.

Sorting & Merging Materials

Do you have a need to accurately and efficiently sort and merge materials? Most distribution centers today require some type of sortation or merging capabilities. If so, you need a product that can boost and maintain your productivity. Span Tech’s line of products efficiently, safely and accurately sort and merge items on a conveyor line, making them the best conveyors for saving you money by eliminating wasted labor and processes.

Laner

Our Laner is able to reliably auto-sort your products into lanes, allowing them to easily be packaged or sent in different directions. This innovative system not only accelerates products into lanes but also virtually eliminates the potential for jamming. With the Span Tech Laner, a typical flow rate of 700 to 800 products per minute can be achieved. This system works best with round, thin products.

High Speed Switch

Span Tech’s High Speed Switch divides products effectively while maintaining product pitch. This switch splits product flow at up to 400 fpm. And the flow can be split evenly or programmed to divert a product whenever you need it. This switch was designed for rigid or bulky products and is most applicable for the packaging, distribution and e-commerce industries.

Powered Divert

The Powered Divert sorting and merging option from Span Tech is extremely valuable for applications where conveyor length is limited and a standard, stationary divert rail would need to be too long to fit (because it would need to use a lesser angle of deflection). The Powered Divert works by helping the product continue moving forward, alleviating unwanted accumulation. Essentially, this feature is a small conveyor flipped up to a 90-degree angle and suspended above your horizontal chain. This product is perfect for non-rigid items or a bagged product. It’s most often used in the food production, packaging, and e-commerce industries.

Elevating Or Lowering Materials

Have the need to change the elevation on your production or packaging line? Whether it’s due to space or production requirements, many warehouses and distribution centers face this challenge. But Span Tech has the best conveyors and dependable systems that seamlessly change the height while keeping your product in tip-top shape. These innovative systems can accommodate heating, cooling and even product orientation needs, so your line runs better than ever. The exact system you choose, though, will depend on your unique space configuration and what you’re moving.

Incline Conveyor

The Span Tech Incline Conveyor is a fully customizable system that can be tailored to your unique needs. These incline conveyors can provide extreme elevation change with speeds reaching up to 400 feet per minute. Wear strips and center support rails provide long-wearing, silent operation. Multiple lengths, belt widths, and curve angles are also available. This system is applicable for those needing to save floor space and elevate products.

Changing-Elevation Topper Lift

The Changing-Elevation Topper Lift can easily and seamlessly tackle difficult angles, product orientation, and drastic elevation change. With a combination of high-friction and conventional chain types, it can incline and decline products at angles up to 60 degrees. The upper chain simply drapes down over the items being moved and rides above the lower transport conveyor, holding the items in place along the way. This design allows for a much steeper angle. Plus, the topper lift allows products to stay upright! The topper lift can handle both rigid and flexible products and is most applicable to the packaging and distribution industries.

Accumulating Materials

Do you have the need to collect products on a conveyor and move them as one group instead of individually? This process works by halting the product on the conveyor and allowing the products behind it to catch up and accumulate together. This need is most often required when packaging multiple products in a single bundle.

Accumulation also acts as a safeguard from shutting down production if a machine at the end of the line is down. You’re able to continue running the line and accumulate product before the downed machine instead of having to shut down the entire line.

Tube Top Chain

The Tube Top Chain was created in order to allow more products to accumulate than previously possible with plain chains. These tubes rotate freely under products that are stopped on the chain, allowing a longer slug of products to accumulate without the risk of damage to the product or conveyor. This product has applications in the beverage, distribution, e-commerce and packaging industries.

Shop Span Tech For All Your Conveying Needs

Let Span Tech help you find the best conveyors for your needs. Browse our entire offering of conveyor systems to find a reliable, durable and effective method of maximizing productivity. Our experienced customer service team can provide you with a totally custom recommendation. Contact us today for more information.