transferring

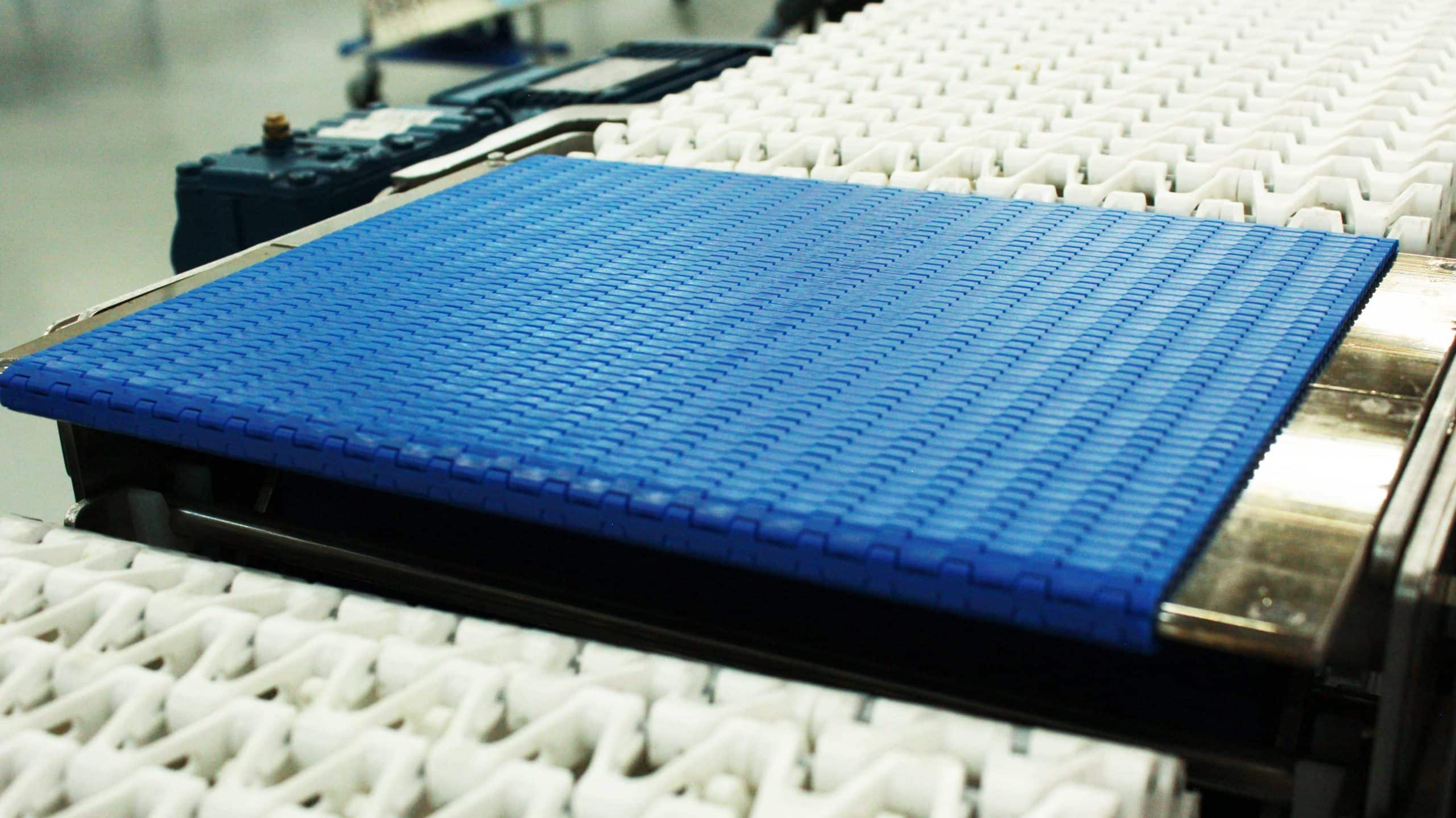

MicroSpan Transfer

Make your end-to-end product movement easier than ever. The MicroSpan transfer is a compact and durable transfer solution that's built to last.

Whether used on one of our conveyor systems or in a custom installation, MicroSpan transfers are the compact answer for end-to-end transport. They also have the capability to be slave-driven from the main conveyor shaft or independently powered by their own gearmotors.

Start Your Estimate

Features

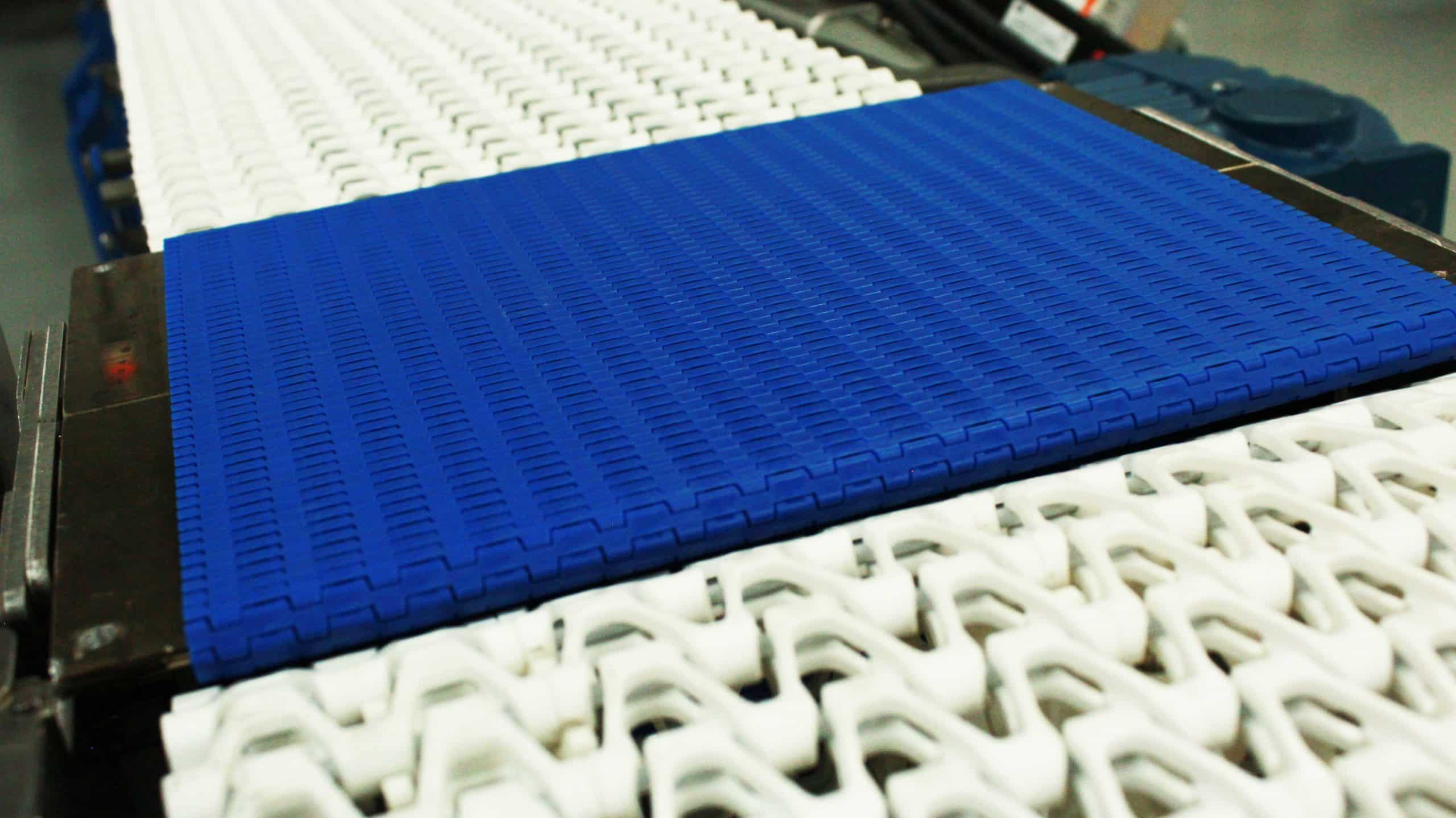

- Power transmission accomplished through an all-gear drive, typically slave-driven from the conveyor shaft

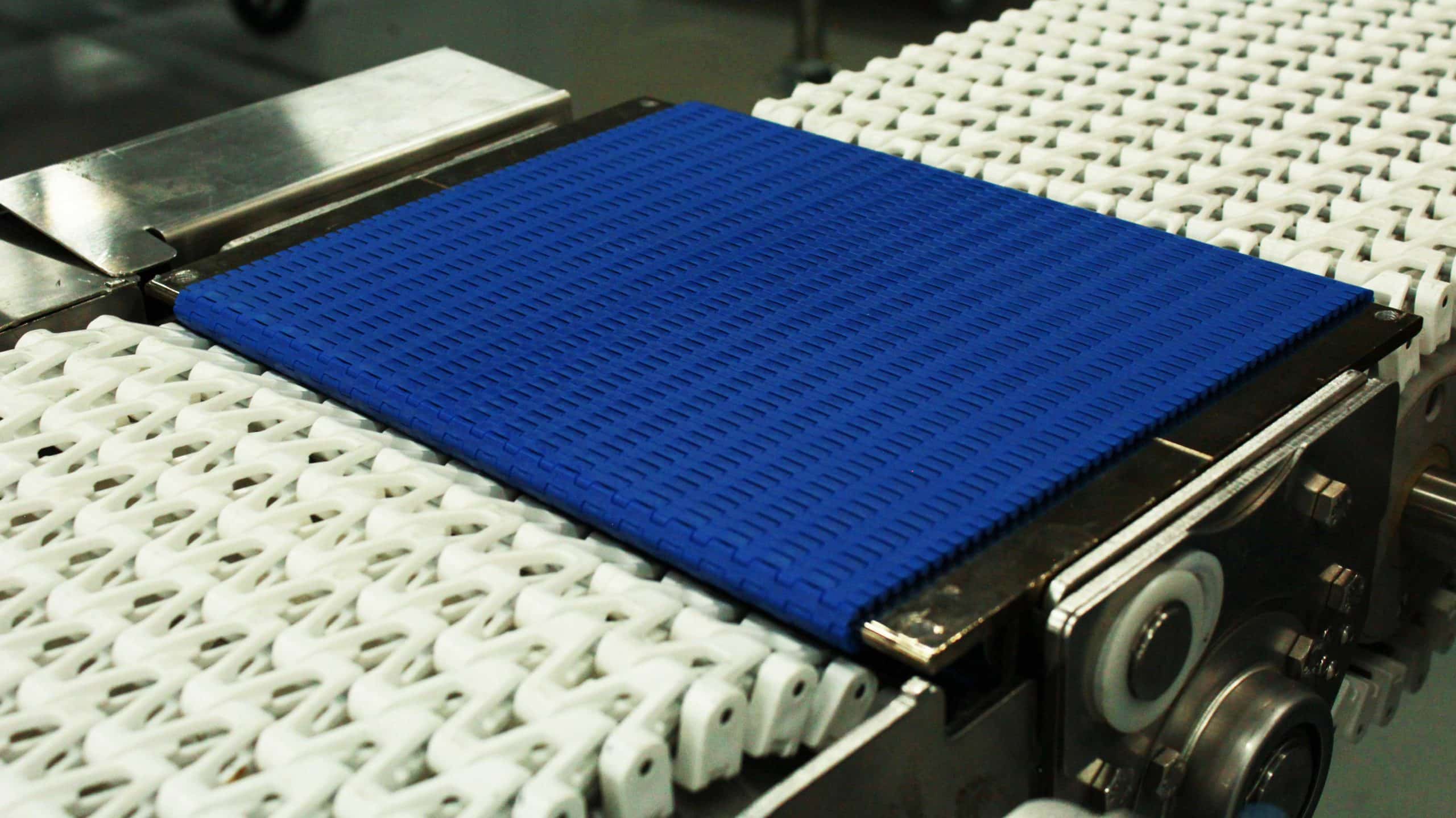

- Variable angle capability, which can be used for decline with “feed off” applications or incline with “feed on” applications

- Easily lifted out when used with MultiSpan conveyors

- Gear motor-powered unit available for when a slave-driven unit is not suitable

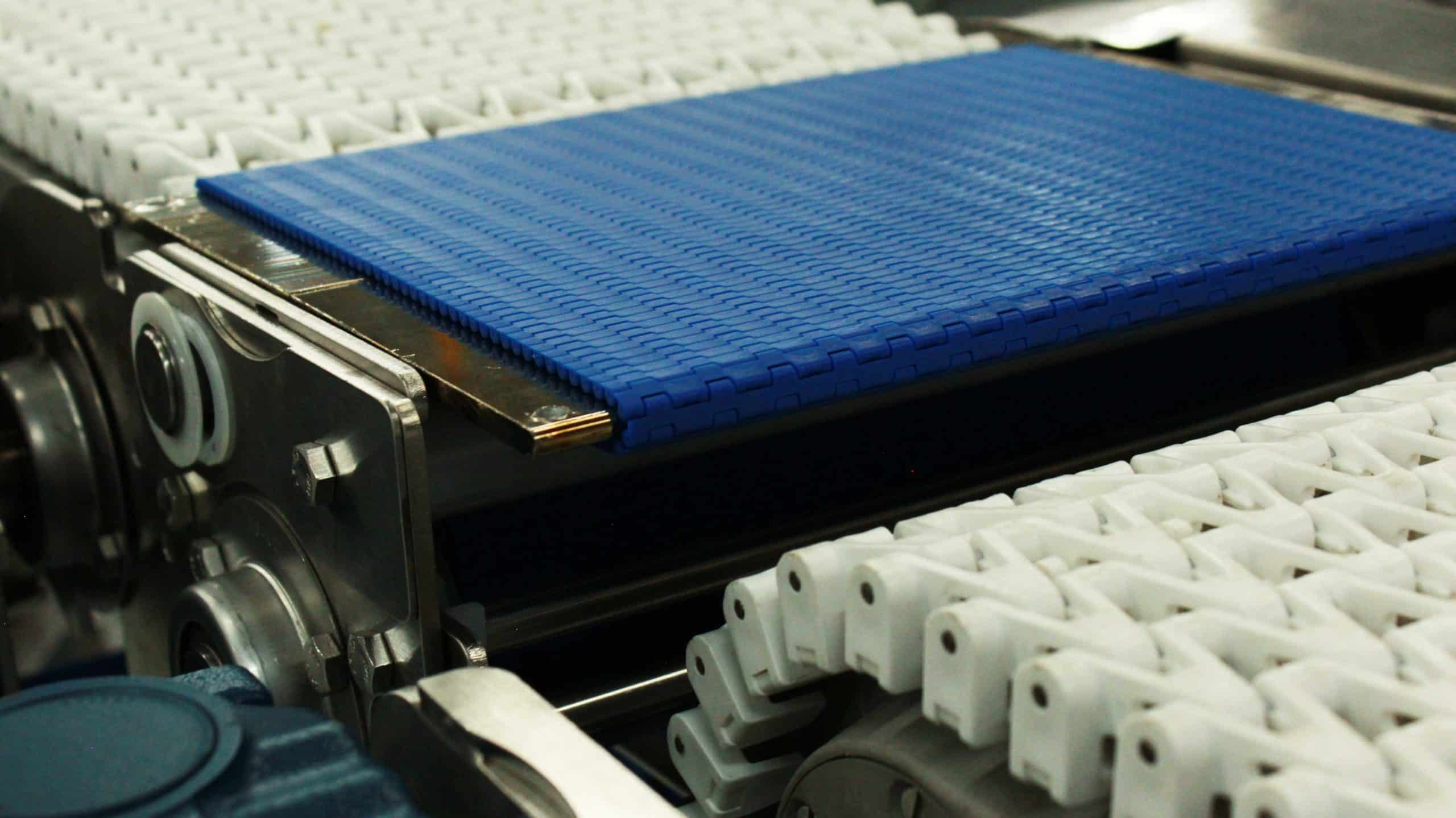

- Nose bar is made of aircraft-grade aluminum and can withstand high wear, heat and washdowns

- Sprocket-driven chain requires no tracking mechanism

Resources

Brochure

Videos

1:33

×