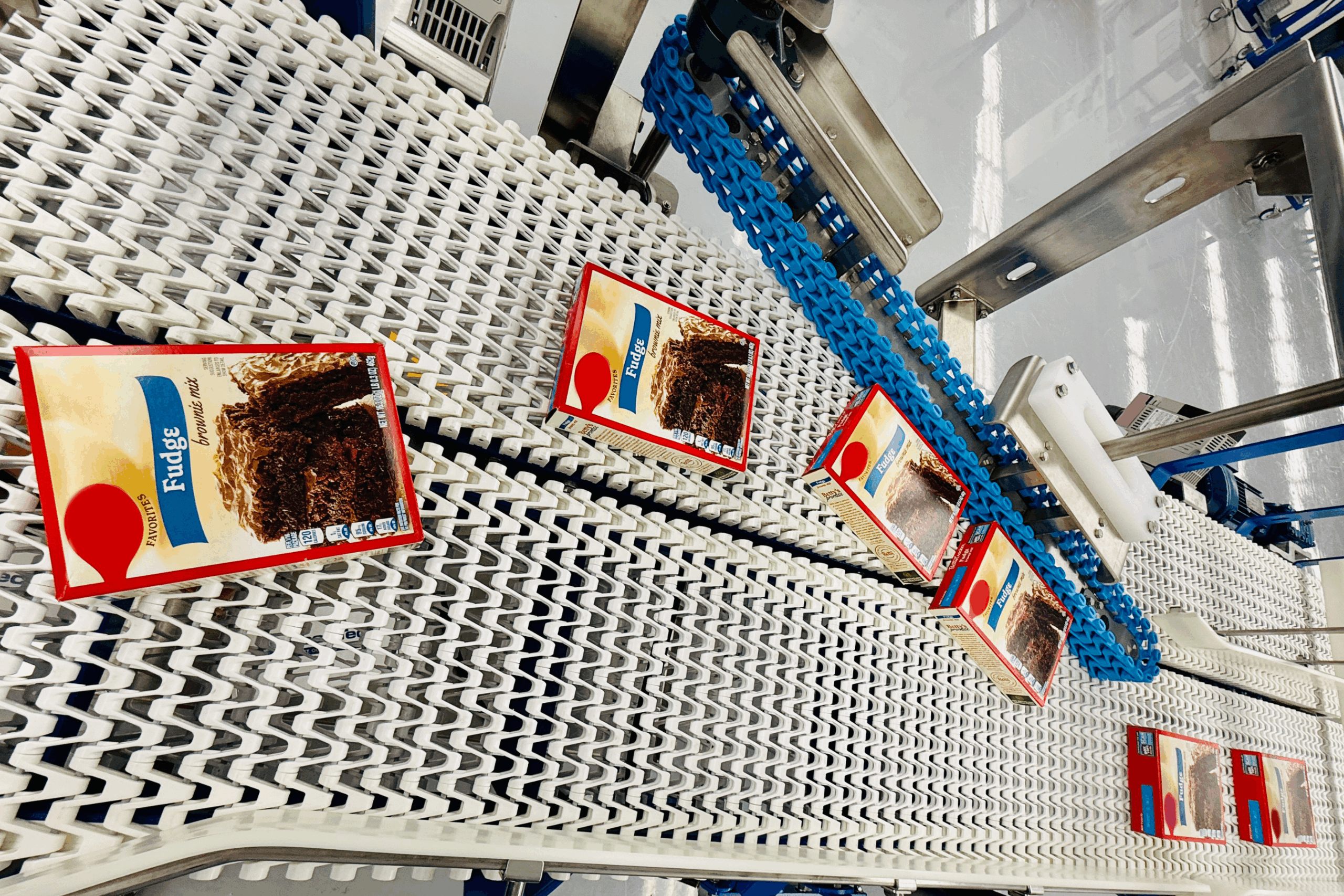

Conveyor Systems for Bakery & Snack Food Industries

Sanitary, Easy to Clean Conveyor Designs

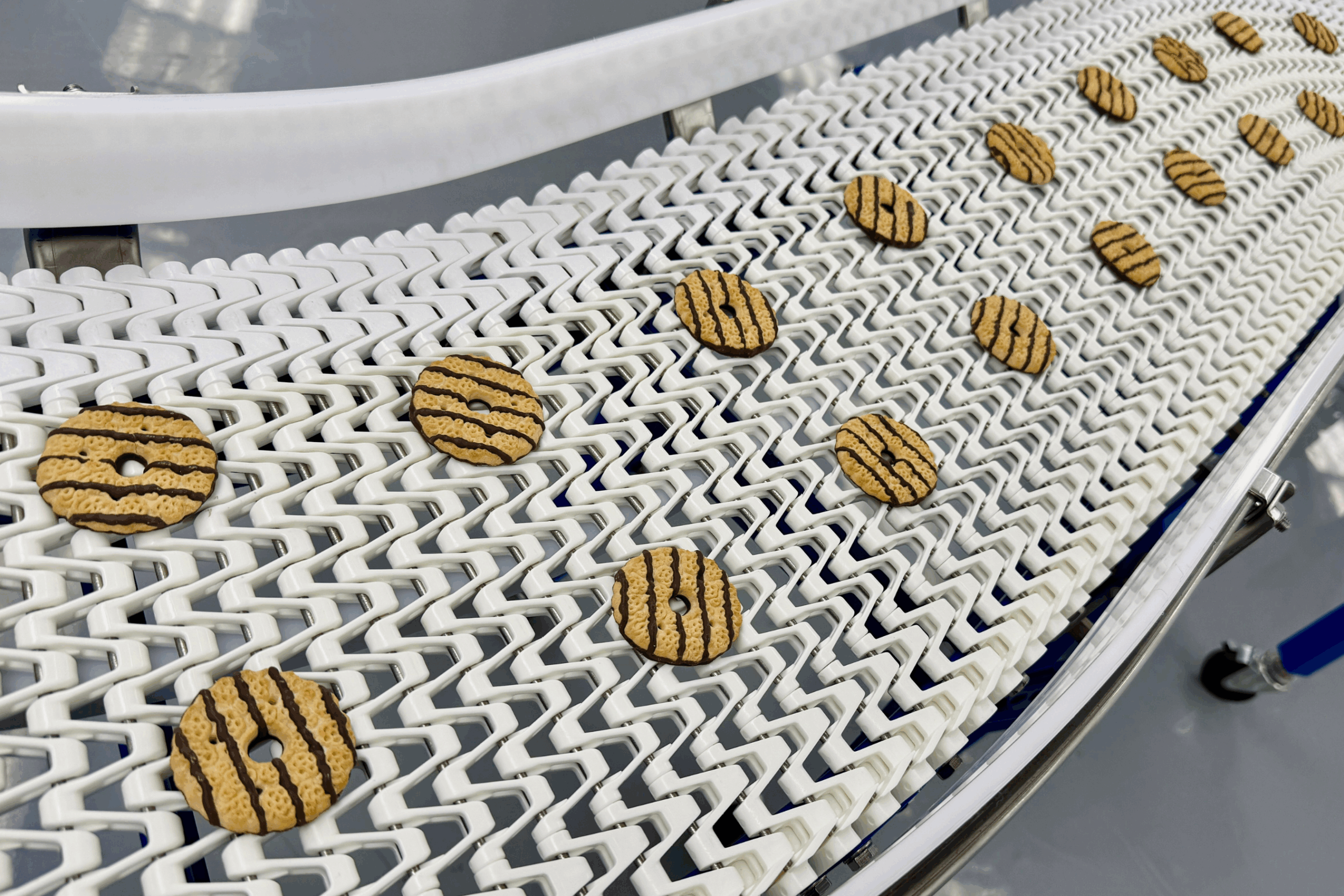

From soft pastries to crispy chips and everything in between, Span Tech’s snack food and bakery conveyor systems are engineered to move delicate, irregular, and high-speed products gently, cleanly, and efficiently.

Whether you’re producing croissants, cookies, crackers, bars, or bagged snacks, our custom baked goods conveyors help improve throughput, reduce breakage, and streamline packaging processes — all while meeting food safety standards..

Snack Food Conveyors Designed for Delicate Products and High Speed Lines

Bakery and snack food items are often lightweight, fragile, and prone to breakage or sticking during transport. Span Tech baked goods conveyors are designed with tight transfers, soft-touch handling, and smooth chain movement, ensuring your products stay aligned, intact, and on schedule.

Our Bakery Conveyors are Ideal for:

- Bread, buns, rolls, and loaves

- Cakes, cookies, pastries, and desserts

- Snack bars, protein bites, and energy squares

- Crackers, chips, pretzels, and bagged snacks

- Frozen dough and par-baked products

- Secondary packaged items: trays, cartons, and multipacks

Efficient Product Flow from Oven to Aisle

Span Tech systems are built to keep your baked goods and snacks moving smoothly, no matter the layout or application. Our baked product conveyors help bridge the gap between baking, cooling, inspection, packaging, and shipping.

Bakery Conveyor System Applications Include:

- Oven-to-cooler transfers

- Spiral conveyors for vertical movement

- Inspection and rejection lanes

- High-speed packaging transitions

- Product accumulation and sorting

- Gentle incline conveyors for bagged snacks or trays

TRUSTED BY BAKERIES & SNACK PRODUCERS NATIONWIDE

Why bakery and snack food companies choose Span Tech:

- Product-friendly design that prevents sticking, flipping, or breakage

- Flexible layouts that adapt to new SKUs or packaging formats

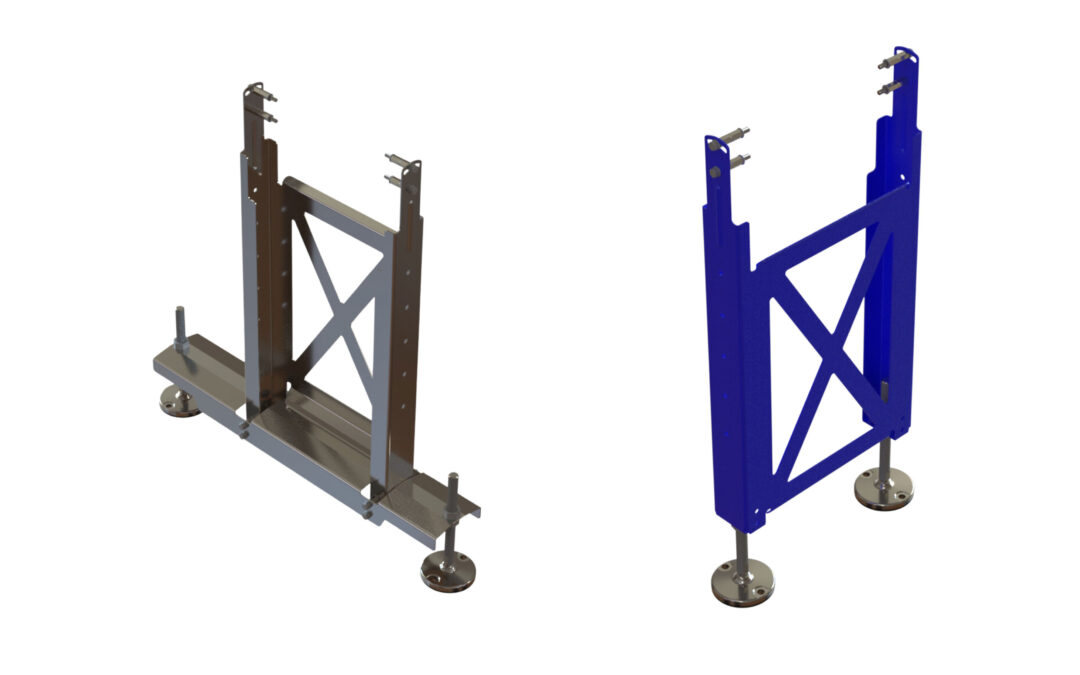

- Bakery conveyor equipment engineered for uptime and long-term durability

- Expert layout and integration support for all production stages

Let’s Get Your Line Rolling

If your bakery or snack food operation is ready to upgrade its conveyor systems, Span Tech offers sanitary, customizable, and efficient solutions built around your specific product flow.

Contact us today for a complimentary plant layout consultation — and let’s design a bakery conveyor system that’s as reliable as your recipes.

Bakery Conveyor System Features & Benefits

Tight Transfer Points to Prevent Damage or Product Tipping

Span Tech bakery conveyors are engineered with ultra-tight transfer points that maintain stability during product handoff. This reduces gaps, prevents tipping, and protects even the most delicate items as they move between sections or machinery. Ideal for lightweight, unstable, or irregularly shaped products.

Smooth-Running Chains with Low-Friction Surfaces

Our proprietary conveyor chains are built with low-friction materials that ensure quiet, efficient, and consistent performance. The smooth operation reduces wear, lowers energy usage, and keeps products gliding effortlessly—perfect for high-throughput packaging lines.

Adjustable Guide Rails and Curves for Irregular Product Shapes

Handle every SKU with confidence. Our adjustable guide rails and custom-tailored curves allow your line to adapt quickly to products of varying widths, shapes, and stability levels. This keeps items perfectly aligned and prevents jams or product migration on the belt.

Modular Layouts for Horizontal, Vertical, and Spiral Configurations

Design your bakery conveyor system your way. Span Tech’s modular architecture allows you to build conveyor paths that move product horizontally, vertically, around corners, or even through spiral elevations. This flexibility helps maximize floor space while optimizing flow and throughput.

Optional Accumulation Zones to Stage Product Before Packaging

Create smarter, more controlled production flow. Our accumulation zones allow you to stage product before downstream processes like filling, sealing, inspection, or packing. This prevents bottlenecks, reduces downtime, and keeps your operation running smoothly.

customizable

Durabile & Efficient

Partnership

FAQs About Conveyors for Baking & Snack Industries

What type of conveyors work best for handling fragile baked goods?

The best baked goods conveyors offer low-friction, smooth-running chains and tight transfer points that are ideal for delicate products like cookies, pastries, and crackers. These features reduce breakage, prevent product tipping, and maintain product orientation throughout the line.

Can Span Tech conveyors withstand the heat and sanitation requirements of baking environments?

Yes. Baking and snack production often involves high temperatures, flour dust, oils, and strict food-safety protocols. Our bakery conveyors offer washdown-ready materials, optional stainless-steel components, and hygienic chain designs that meet FDA and industry sanitation standards.

How do bakery conveyors improve efficiency in snack packaging lines?

Modular conveyor layouts allow for smooth transitions between ovens, cooling tunnels, inspection equipment, and packaging stations. Optional accumulation zones also help regulate flow, reduce bottlenecks, and keep products moving continuously—even during downstream pauses.

Are Span Tech conveyors customizable for different product sizes and shapes?

Absolutely. Baking and snack operations often run a mix of SKUs with different widths, weights, and fragility levels. Adjustable guide rails, flexible curves, and multiple chain options make it easy to configure a bakery conveyor system that handles everything from small crackers to large loaves.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.