Conveyors for the Meat & Poultry Industries

Meat Processing Conveyors Built For Sanitation Driven Environments

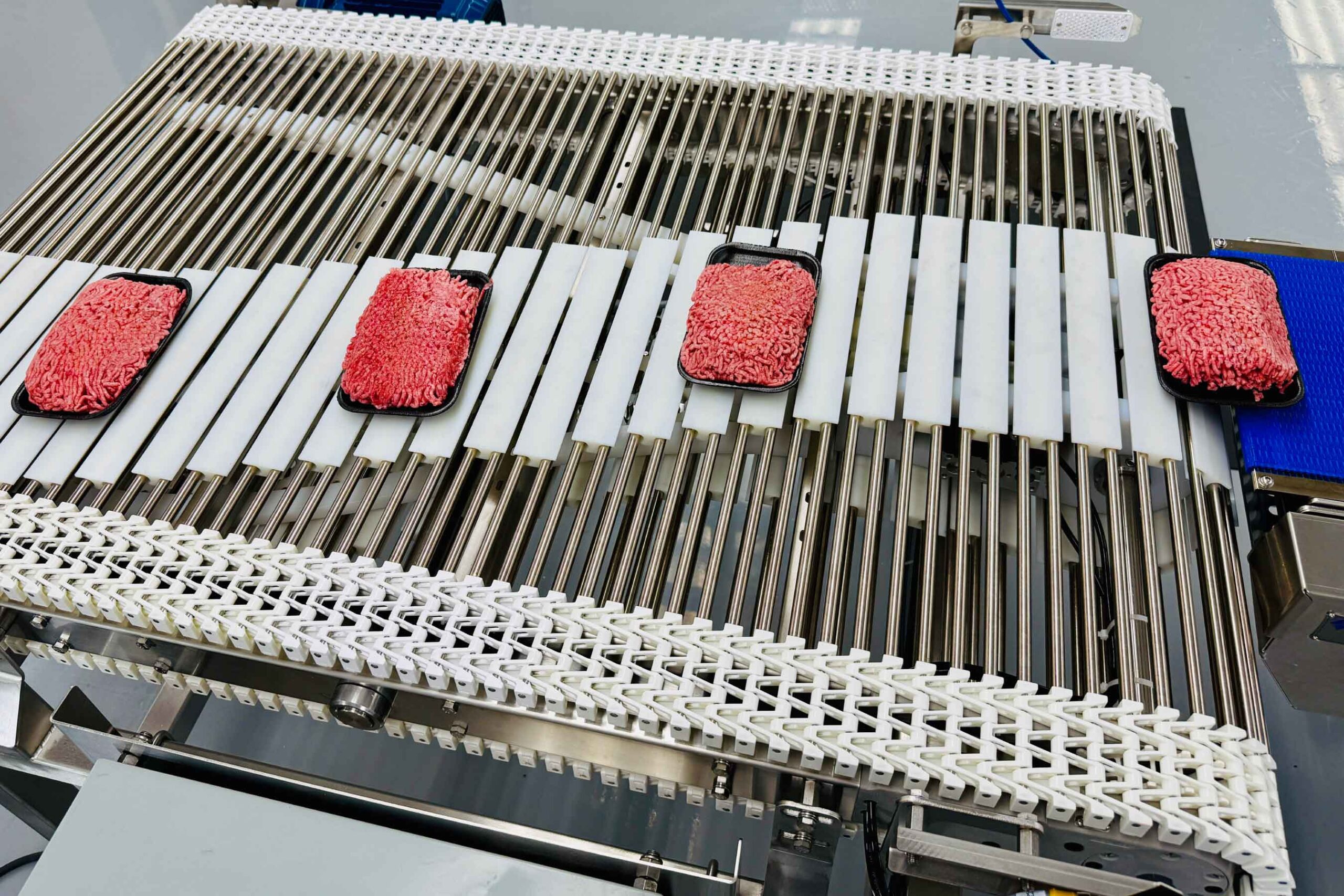

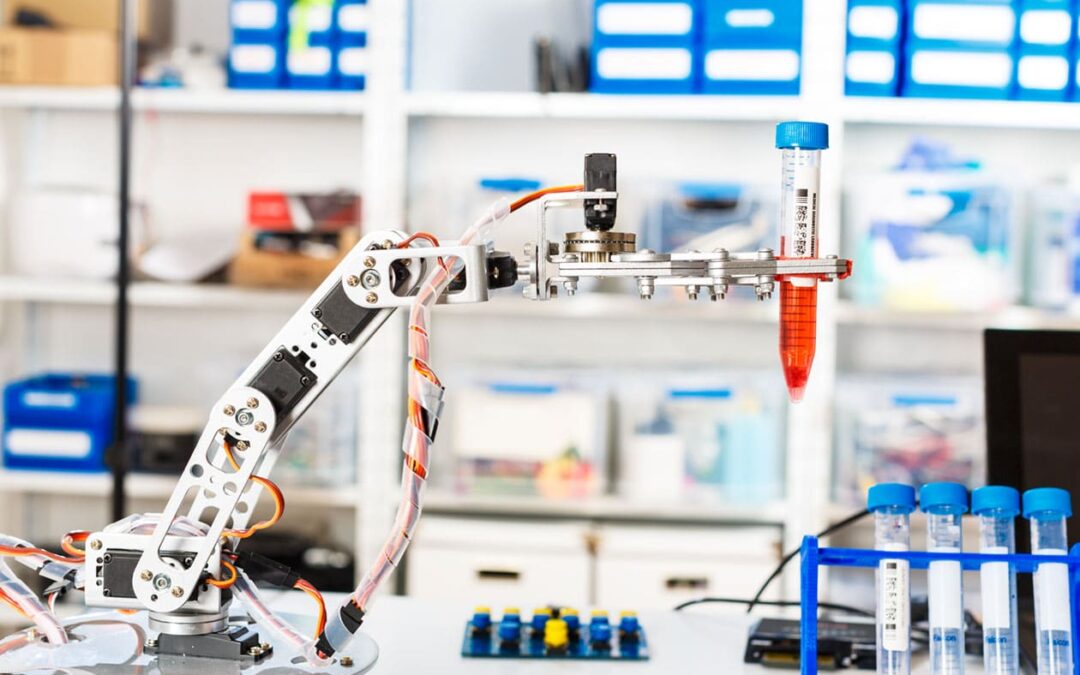

In the meat and poultry industry, precision, hygiene, and throughput are non-negotiable. Span Tech’s custom meat conveyor solutions are designed to meet the demanding conditions of meat and poultry processing — from raw product handling to packaging — with the strength, sanitation, and configurability your operation requires.

Your facility faces constant washdowns, USDA inspections, and strict hygiene standards. Our meat and poultry conveyors are engineered for sanitary performance in wet, cold, and raw environments, while also minimizing maintenance and manual intervention.

Meat Conveyor Systems Promote Safe & Reliable Meat Handling – From Cut to Pack

Span Tech’s meat conveyors are optimized to move raw and cooked meats, poultry parts, ground products, and case-ready trays — without compromising product integrity or line efficiency. Whether you’re slicing, batching, marinating, chilling, or packing, our meat conveyor systems are engineered to withstand the harshest environments while improving product flow and reducing contamination risk.

Our Meat Processing Conveyors are Ideal for:

- Boneless and bone-in poultry

- Whole muscle cuts (beef, pork, chicken)

- Ground meat patties or tubes

- Cooked and packaged deli meats

- Case-ready meat trays and vacuum-sealed packaging

Designed for Throughput, Durability and Control

In high-output protein facilities, downtime is expensive. Span Tech meat conveyor systems are designed to minimize stoppages and product damage while optimizing efficiency at every stage.

Key Benefits of Span Tech’s Meat & Poultry Conveyor Systems:

- Modular, customizable layouts for exact facility specs

- Conveyors that maintain product spacing, orientation, and stability

- Spiral and incline conveyors for vertical space savings

- Options for product sorting, diverting, and accumulation

- Energy-efficient motors and sealed bearings built for wet environments

OVER 40 YEARS OF SANITARY CONVEYOR EXPERTISE

Span Tech has been trusted by major meat and poultry producers for decades. From small meat-processing lines to full-scale poultry operations, our team understands the unique requirements of protein handling and brings deep knowledge in designing meat conveyor systems that comply with USDA and FDA standards.

Why processors choose Span Tech:

- Proven track record in meat and poultry operations

- Design support for USDA-compliant production zones

- Chains and belting that handle heavy, moist, or sticky products

- Built to reduce labor fatigue and improve operator ergonomics

Let’s Design Your Meat or Poultry Conveyor System

Whether you need to improve your deboning line, reduce sanitation downtime, or speed up tray packing, Span Tech has the hygienic, efficient, and high-performing meat processing conveyors you need to meet demand and compliance requirements.

Contact us today for a custom layout review or to schedule a free on-site conveyor consultation.

Meat Processing Conveyor Features & Benefits

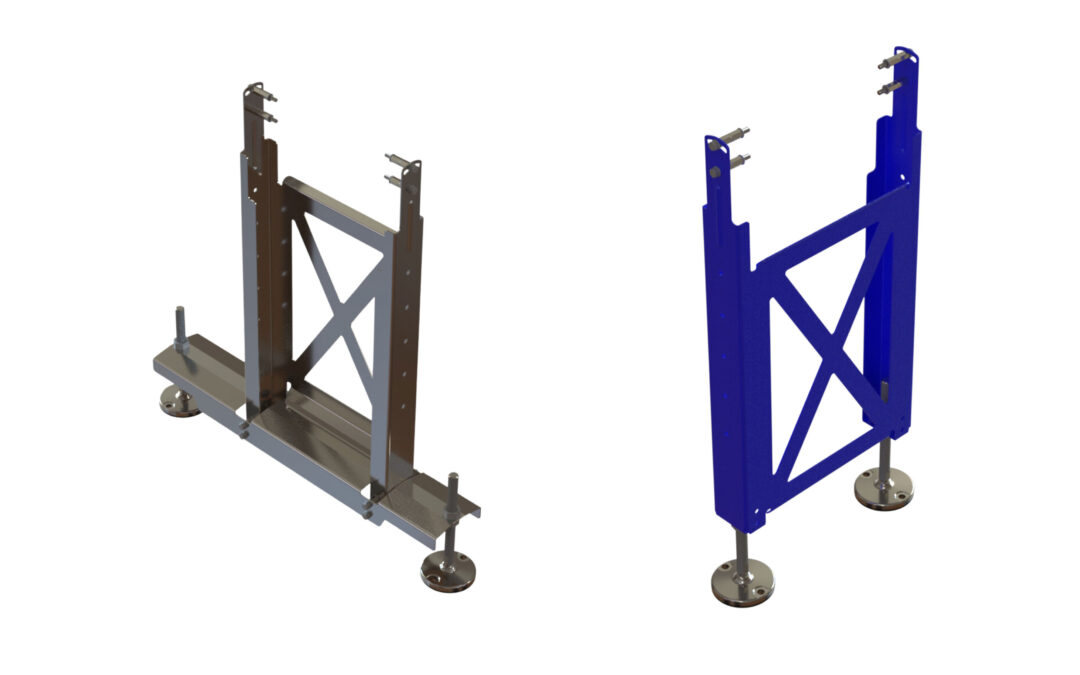

Stainless steel construction

Built for hygiene-critical environments, our meat conveyors feature stainless steel frames that stand up to daily high-pressure washdowns without corrosion or wear.

CIP and COP compatible components

Compatible with Clean-In-Place (CIP) and Clean-Out-of-Place (COP) systems, our poultry conveyors streamline sanitation processes and reduce labor time between product runs.

Tool-less chain removal

Perform rapid sanitation with minimal downtime. Easily remove the chain and access internal surfaces without tools.

Sanitation-friendly construction

Fabricated for easy cleaning in environments prone to flour, corn dust, or particulate buildup, supporting hygiene compliance.

customizable

Span Tech offers tailored solutions to meet specific operational needs, whether for delicate handling or heavy-duty operations.

Durabile & Efficient

Span Tech conveyors are engineered for durability, built with high-quality materials to withstand tough environments and reduce maintenance costs. Their robust design ensures long-lasting, reliable performance, maximizing uptime and productivity for any operation.

Partnership

OEMs, Distributors, Integrators and End Users, choose Span Tech for innovative and reliable conveyor solutions tailored to unique needs. Our systems offer seamless integration, durability, and reduced maintenance, maximizing ROI and efficiency.

FAQs About Conveyors for the Meat & Poultry Industry

Are Span Tech conveyors safe for meat and poultry processing environments?

Yes. Our meat processing conveyors are designed with USDA-compliant materials, stainless steel construction, and open-frame designs to meet the strict hygiene standards of meat and poultry facilities.

Can Span Tech meat & poultry conveyors handle daily washdowns and harsh sanitation chemicals?

Absolutely. Span Tech conveyors are built to withstand frequent high-pressure washdowns and exposure to sanitation chemicals commonly used in meat processing plants.

Are Span Tech meat conveyors compatible with metal detectors and x-ray inspection systems?

Yes. We offer metal detector-friendly conveyor sections and custom configurations to integrate seamlessly with inspection equipment.

What types of meat and poultry products can your conveyors handle?

Our meat conveyor systems can handle everything from raw cuts and packaged products to boxed meats, sausages, poultry parts, and cooked items — all with care and precision.

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

“It made our life a whole lot simpler and easier” when speaking about EZGUIDE Adjustable Guiderail

SpanTech’s EZGuide rail system has greatly improved change over times on our bottle filling line. We fill a wide range of bottle sizes and styles. The EZGuide system makes it easier and quicker to adjust between larger and smaller containers. One great feature is the lack of protruding rods from the sides of the conveyors. We are looking at installing this rail system on more filling lines in the near future.

I feel like Span Tech offered us more diversity, custom conveyors, especially for the products that we run and how we run them.

The sales and service personnel at Span Tech are always very professional and helpful throughout the entire process, from design phase, quoting, order processing and delivery of equipment. Quality equipment, professional service and knowledgeable personnel are why Arr-Tech’s choice for conveyor systems will always be Span Tech.

Paradise Tomato Kitchen has used Span Tech conveyors for our sanitary food pouch conveying systems for many years. These sanitary conveyors have provided the best cost of ownership, or the lowest net present value, of any processing conveyors we have used in our food manufacturing plants. These conveyors are easy to widen, lengthen or design for curves and angles to convey our flexible pouches between unit operations.

The quality of this product speaks for itself. Where the difference lies is in the quality of the organization. The whole Span Tech organization – Sales, Engineering, Service – works to serve customers’ needs, not just sell conveyors.