5 Conveyor Transfer Methods: How to Transfer Products with Seamless Precision

Importance of Precise Product Transfers

Precise product transfers are exactly what the term suggests: the accurate, reliable movement of goods from one point to another within a manufacturing or distribution setup. This involves minimizing product damage, reducing downtimes, and ensuring a streamlined operational flow. But why is precision when transferring products so crucial?

Cost-Effectiveness

Imprecise transfers can lead to product losses due to damage or inefficiencies that slow down the production line. Both scenarios contribute to increased operational costs, which can impact the profitability of the business.

Quality Assurance

In industries such as food processing or pharmaceuticals, the cost of imprecise transfers isn’t just monetary; it can also compromise the quality and safety of products. Precise conveyor to conveyor transfer of products helps maintain the integrity of goods, ensuring they meet quality and safety standards.

Scalability

As a business grows, its supply chain complexities often grow exponentially. Precise transfer systems are scalable, making it easier to adapt to increased production demands without a significant revamp of the existing setup.

Operational Efficiency

A reliable conveyor transfer system minimizes downtime, enhancing operational efficiency. This ensures that the production schedules are met and customer commitments are honored, thus maintaining a business’s reputation for reliability and service.

Compliance

Various industries have strict regulations governing the transport and handling of goods. Precise transfer methods are designed to meet or exceed these standards, helping businesses stay compliant and avoid costly legal issues.

Types of Industries that Require Conveyor Transfer Systems

Conveyor systems are not a one-size-fits-all solution; they are a versatile tool applicable across a broad spectrum of industries. Here are some key sectors where conveyor transfer products play a pivotal role:

Food and Beverage

In this sector, conveyor systems are employed to move raw ingredients, finished products, and everything in between. Hygiene and speed are of the essence for food and beverage production, and Span Tech’s solutions are engineered to meet these specific needs.

Pharmaceuticals

Precise and gentle handling is critical in the pharmaceutical industry to ensure the integrity of medicines and other products. Transfer conveyor systems are often designed with this level of care and precision in mind.

Automotive

Speed and durability are the name of the game in automotive manufacturing. Conveyor systems are used to move parts swiftly and efficiently through assembly lines, aiding in quick production cycles.

Retail and E-commerce

From warehouses to sorting facilities, conveyor transfer systems are crucial in managing the high volume of goods that need to be sorted, packed, and shipped for retail and e-commerce facilities.

Mining and Construction

The heavy-duty requirements of these sectors call for robust conveyor systems capable of handling bulk materials like ore and construction supplies without the risk of breakdowns.

5 Common Conveyor Transfer Methods

Navigating the myriad options for conveyor transfer can seem daunting, but understanding the different methods available can make all the difference in optimizing your operations. Various methods are suited for distinct types of goods, production speeds, and specific industry needs. Let’s take a look at five key conveyor transfer methods, each with its own set of advantages and applications.

90-Degree Transfer

This method allows for a smooth transition of products at right angles. Often used in sorting and distribution centers, this conveyor transfer method is essential for directing goods to different routes or machines.

Side-to-Side Transfer

Best suited for merging two parallel lines or for shifting products to an adjacent conveyor belt, the side-to-side transfer is commonly seen in packaging and assembly operations.

Dead Plates

A dead plate involves a smooth, flat surface placed between two conveyor belts to facilitate the transition of products. Although simpler in design, it is highly effective for specific applications like bottle filling or sorting.

Retractable Tail

Retractable tails are specially designed conveyor segments that can be withdrawn to allow products to pass onto another conveyor line. This is especially useful in multi-line setups where goods may need to switch lanes.

End-to-End Transfer

The simplest of all methods, end-to-end transfers involve moving products from one conveyor belt to another in a straight line. This method is versatile and can be used in various industries.

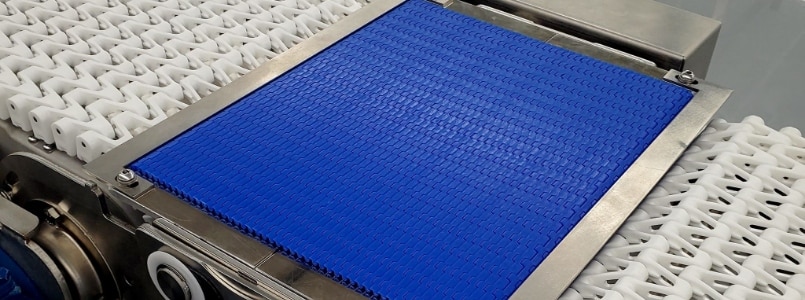

Trust Span Tech to Improve Your Conveyor Transfer Capabilities

If you’re on the hunt for a conveyor system that offers seamless precision, durability, and a high level of customization, look no further. Span Tech has a range of solutions that are engineered to meet your specific conveyor transfer needs. Don’t settle for a one-size-fits-all solution when you can have a system tailor-made for your operation. Discover how we can help you optimize your production line; let’s move your business forward, together.