EZGUIDE™ Conveyor Guide Rails

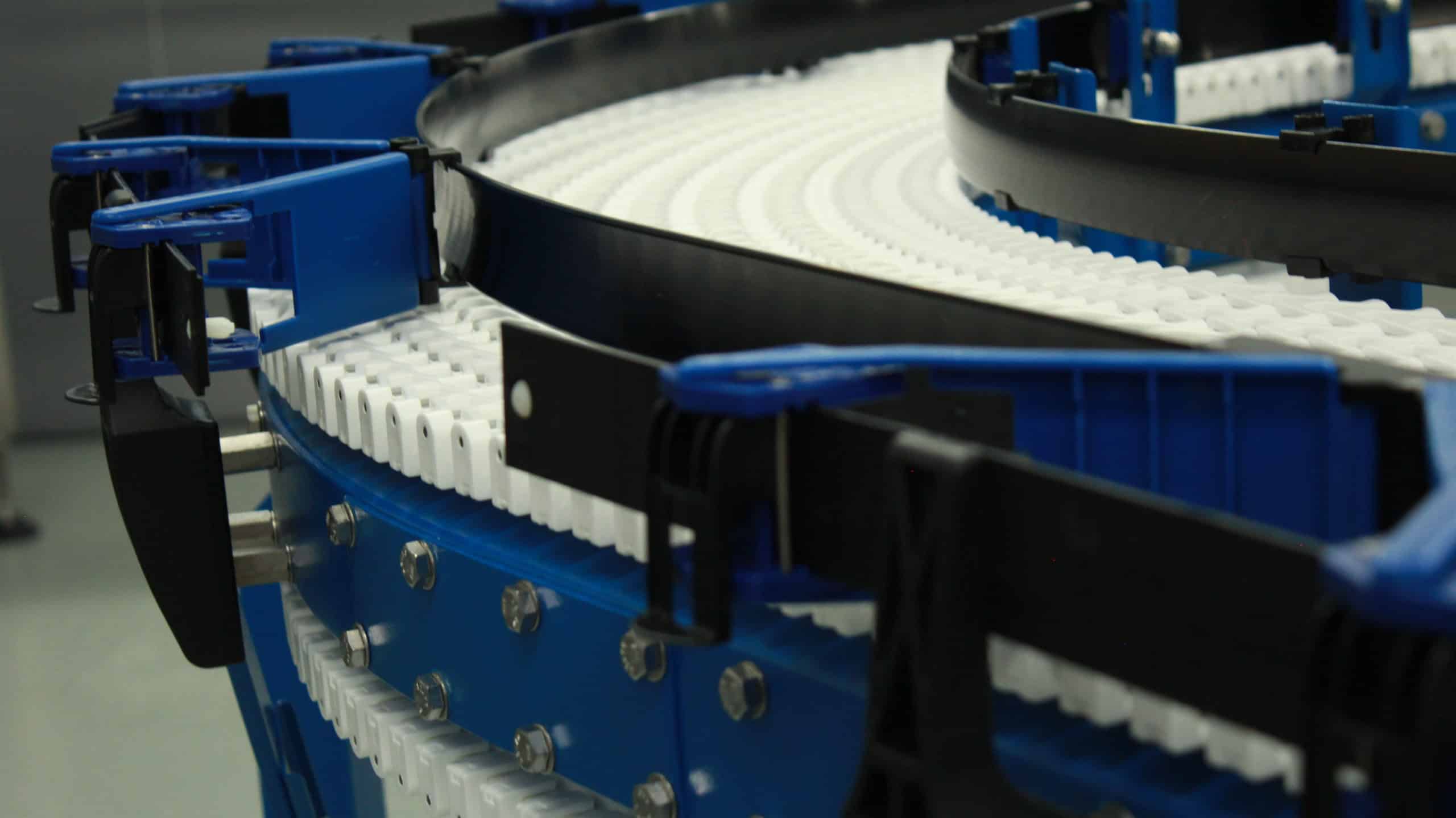

Span Tech has introduced a new line of adjustable guide rail to the marketplace, EZGUIDE™. This technology revolutionizes the way you look at and use standard guide rail.

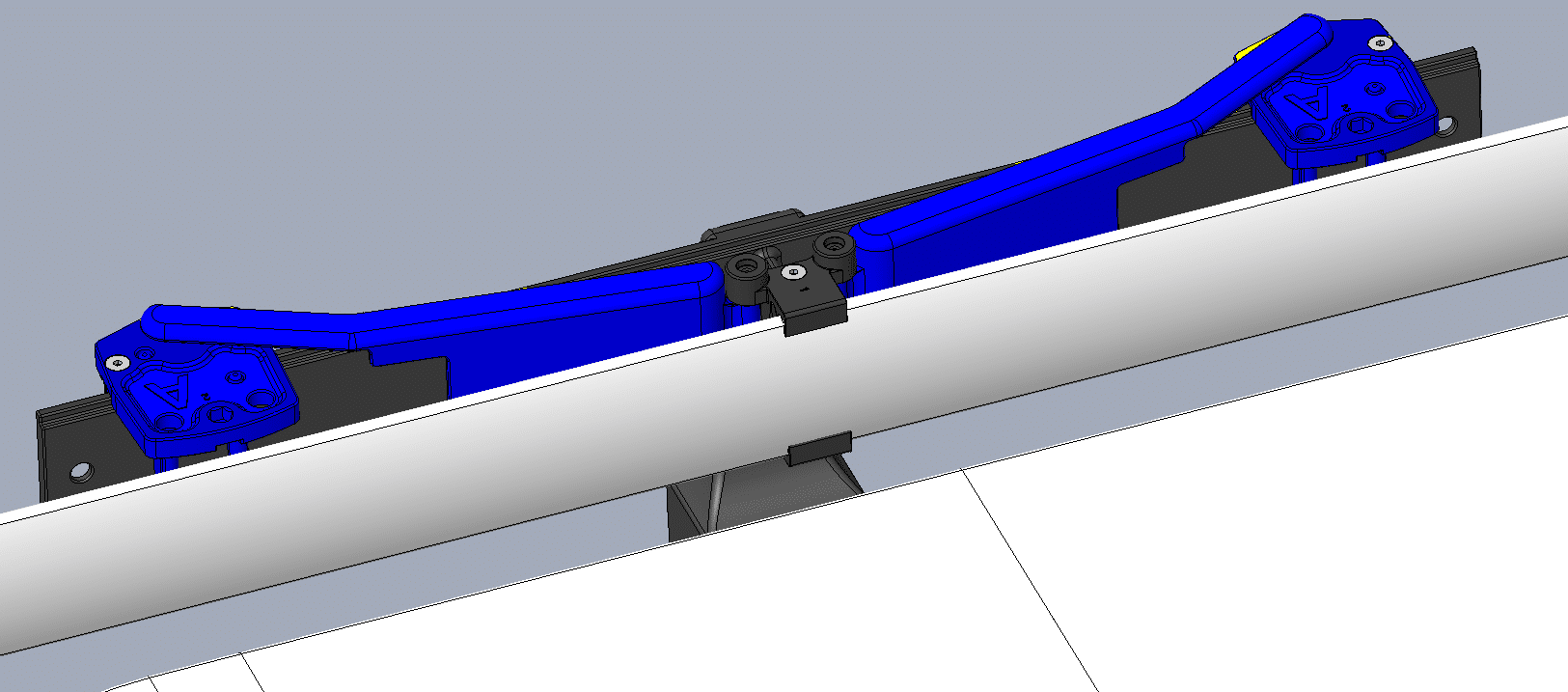

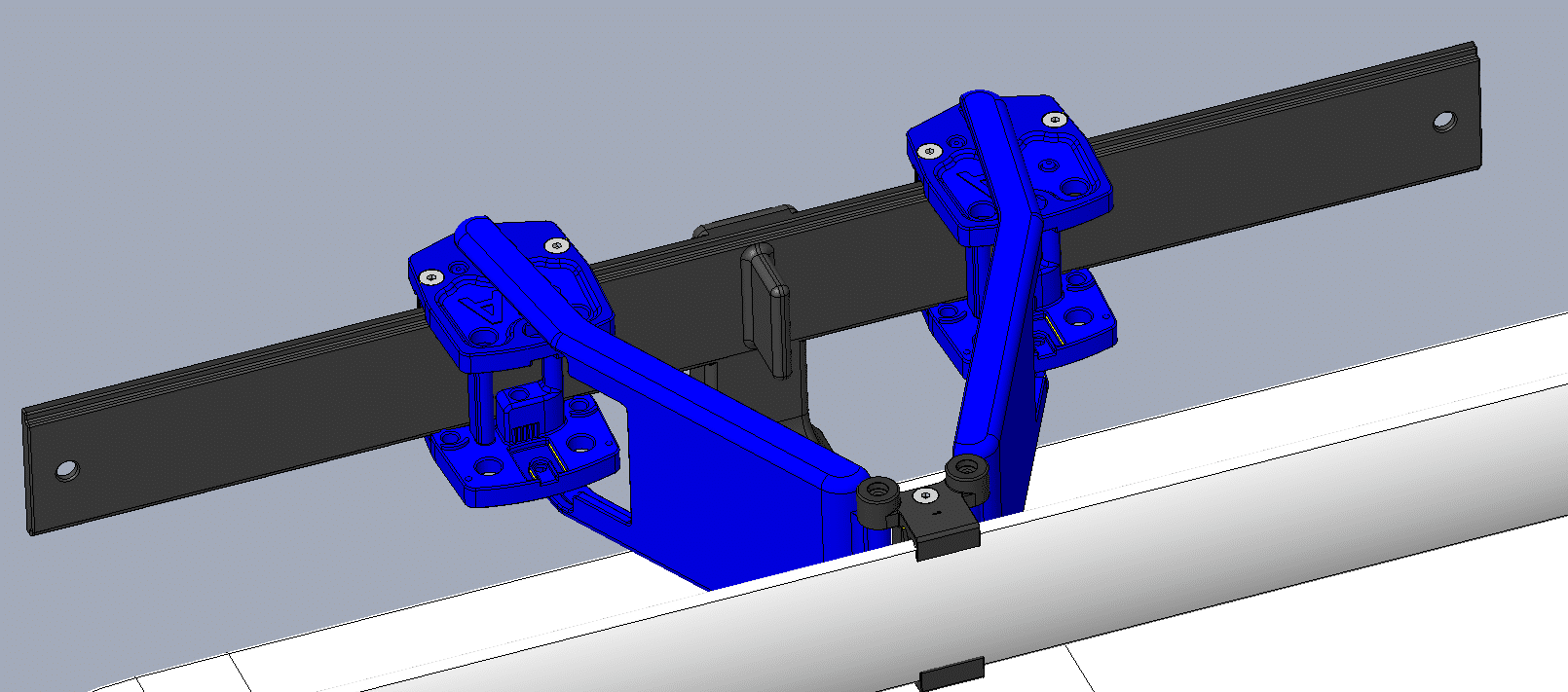

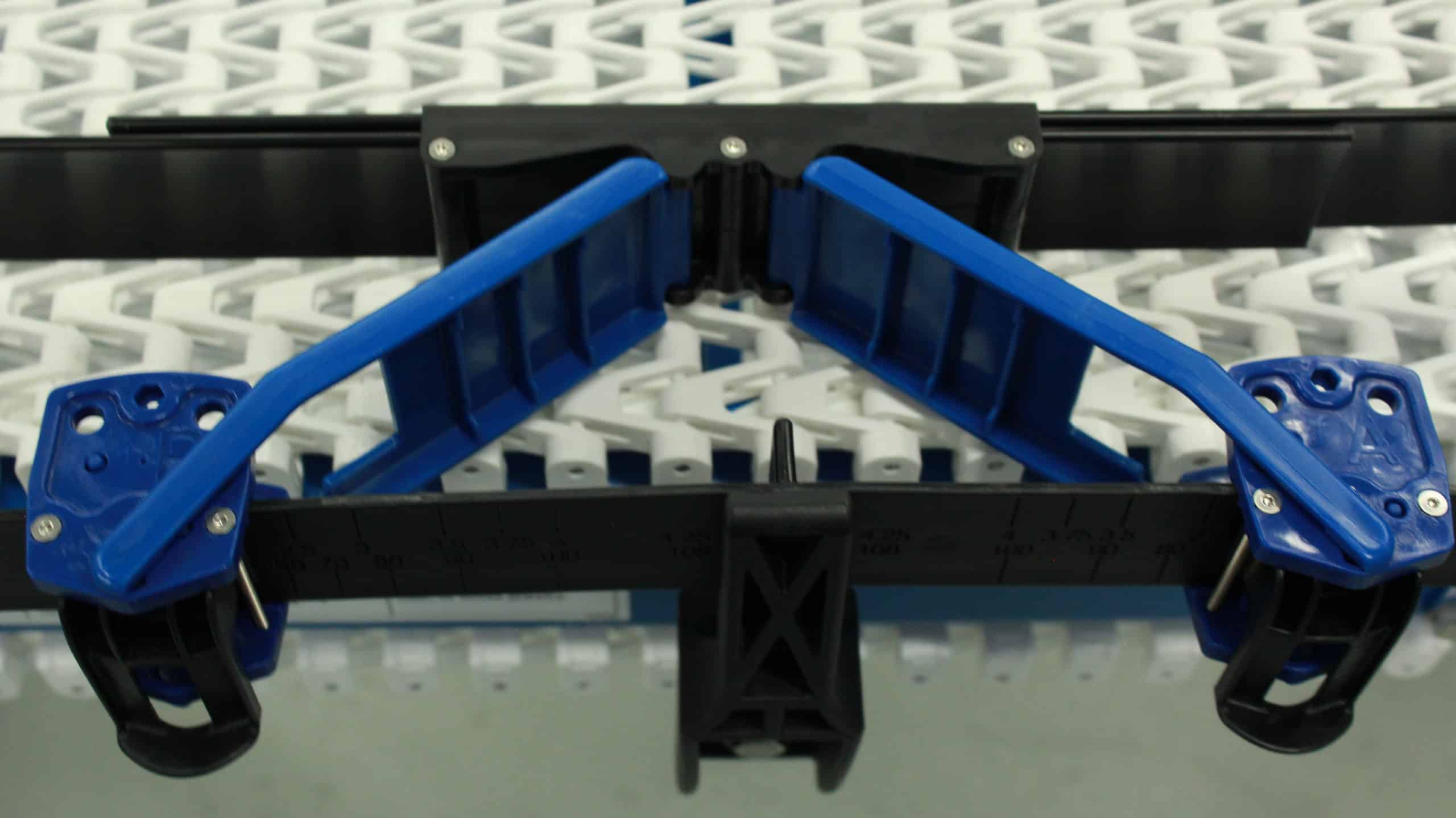

The most notable feature of the EZGUIDE™ conveyor guide rail system is it does not have any protruding brackets or rods which could be a major safety hazard. Traditional conveyor guide rails use a solid-mounted rod to mount their guide rail. When the rail is adjusted to its “retracted” position, these rods stick out from the sides of the conveyor, becoming a place where someone can easily get their clothes or other body parts caught. The EZGUIDE™ system does not have any mechanical components which protrude from the sides of the conveyor during adjustment. All the mechanics are done without the need to protrude past the conveyor, keeping everything safe for those walking close to the conveyors.

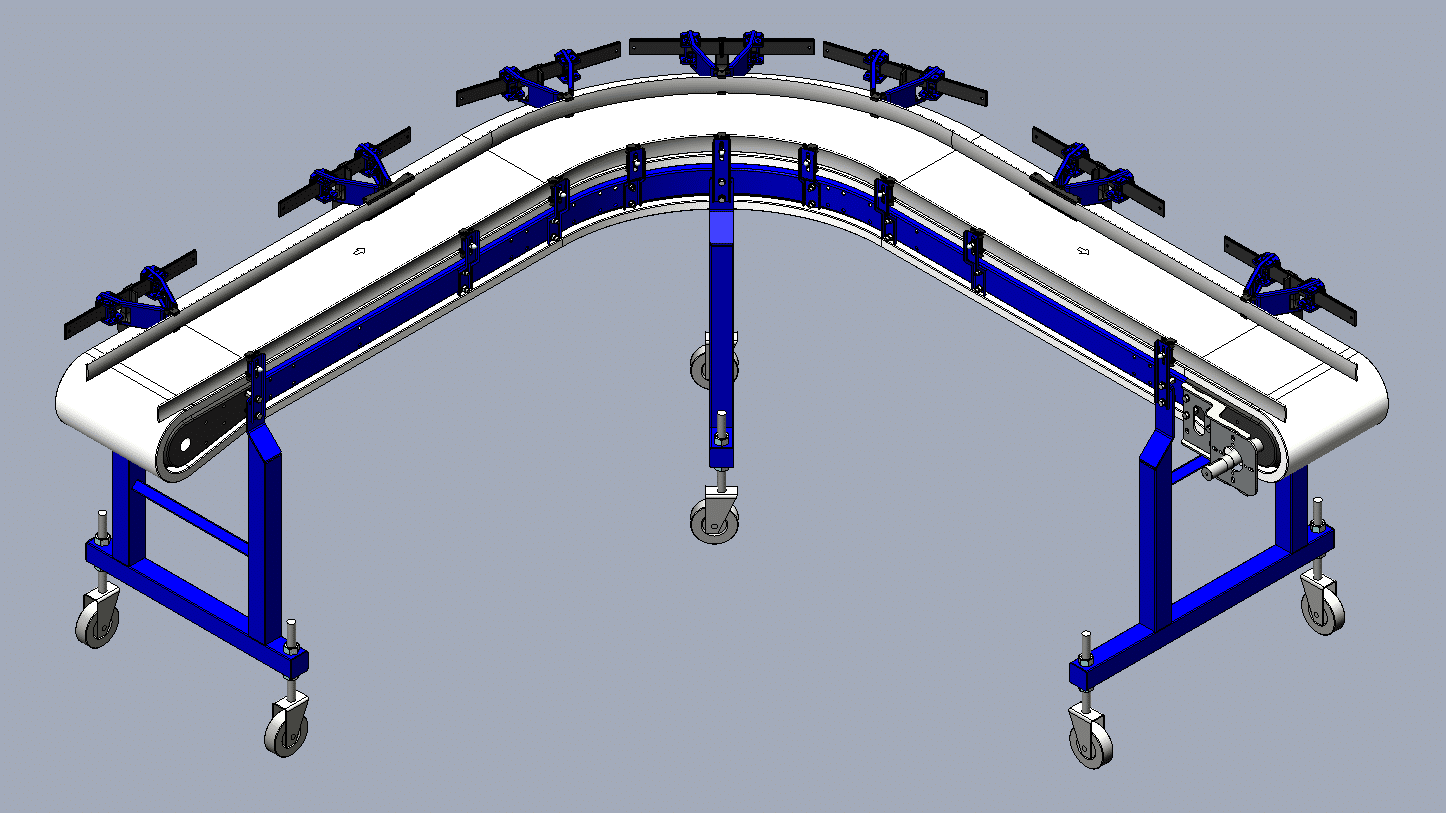

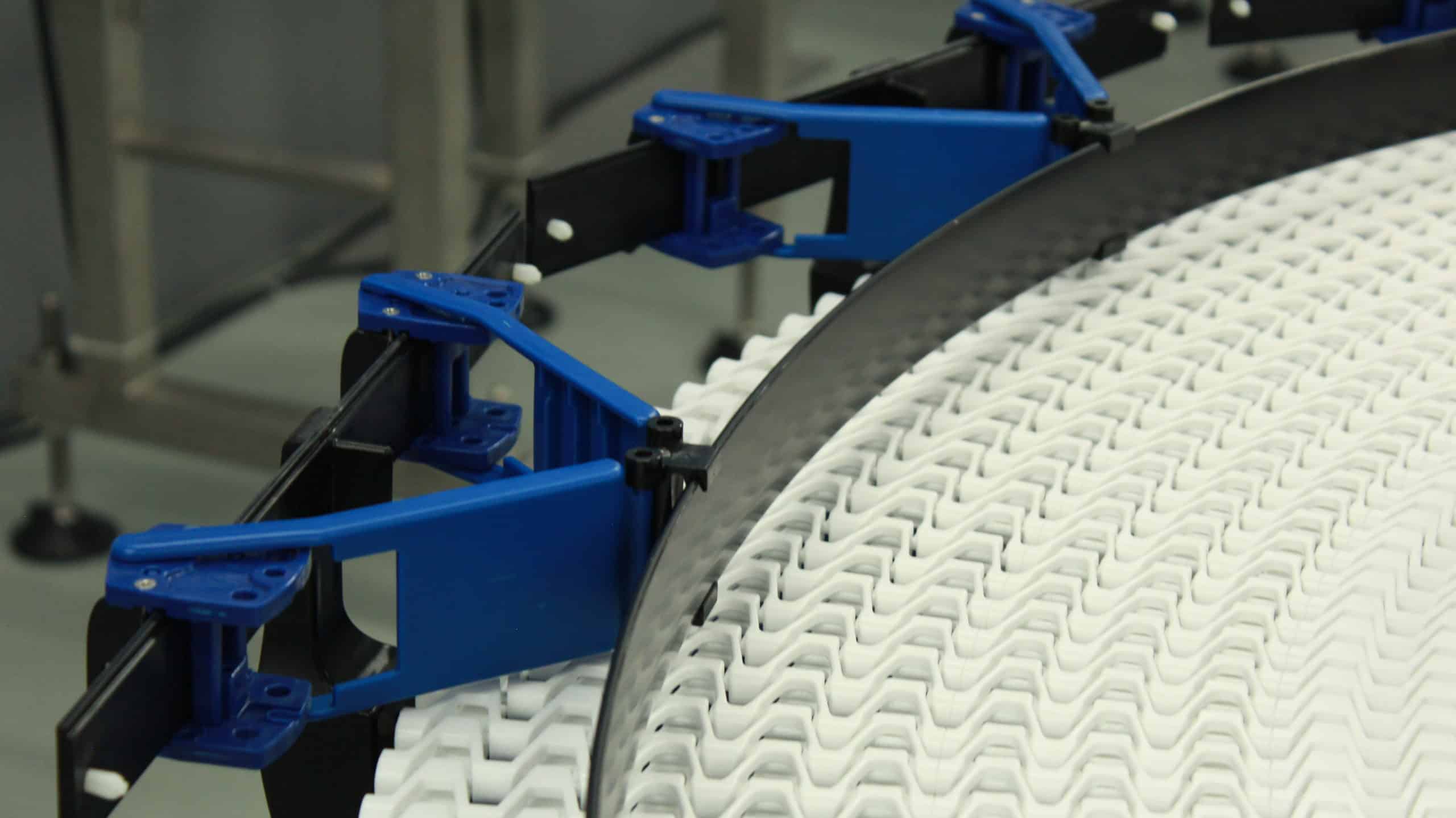

Conveyor Guide Rails Adjustable Through Curves

Another feature of the EZGUIDE™ conveyor guide rails is it is designed to remain adjustable through curves. That is, the radius of the guides can change as the guide width is increased/decreased in the curve. While there are many traditional guide rail systems which can be made to adjust their width in straight sections, there are very few that can truly be adjustable through a curved portion of conveyor. The reason is because changing the radius of a section is difficult – the guides must bend, and the length of the guide has to increase/decrease as the radius is changed. EZGUIDE™ conveyor guide rails handle both of those problems with its unique design.

Contact the EZGUIDE Department for any questions –> Email Us

EZGUIDE™ Conveyor Guide Rails Available in 2 options:

- Fixed- This option provides a basic fixed-width guidance solution for single-width products and/or safety concerns (such as overhead conveyor installations).

- Manual Adjustment- This is the entry-level system which is adjusted by manually unlocking the guides and positioning the guide rails by hand. This is very similar to almost all other guide rail systems on the market.

Features

- Multiple Variations.

- Eliminates Protruding brackets and rods for safety.

- Ability to remain adjustable through curves.

- Universal bracket allows for installation on ANY conveyor.