The Difference with E-Commerce Businesses

The nature of orders has profoundly changed with the amazing growth of e-commerce businesses. Where a typical retail-oriented warehouse once handled 300 orders, each containing thousands of items, today’s e-commerce-based system must process thousands of orders, each consisting of an average of 1.5 items.

The type of packaging has changed, as well. Warehouses equipped with traditional conveyor sortation systems were centered on handling full cardboard cartons, but e-commerce businesses, looking to save material and shipping costs, turned to poly bags as their packaging of choice.

The “Amazon Effect” is another consideration. Consumers began to expect sometimes unrealistic shipping times, thanks to Amazon’s one- and two-day delivery promises.

All of these changes stressed traditional conveyor sorter systems to the breaking point.

The Challenge for Material Handling Companies

The switch to handling single-item orders permanently altered the calculus for material handling companies. The increased volume of orders threatened to overwhelm many companies that were unprepared for the onslaught.

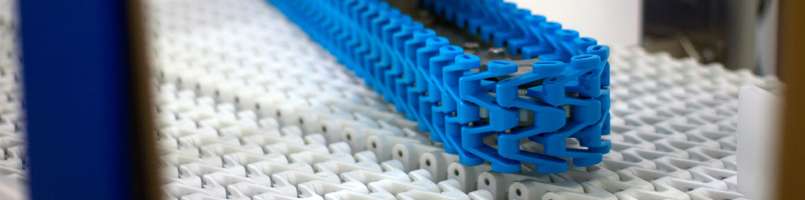

The developing reliance on poly bags brought additional challenges for those using traditional conveyor sortation systems. Roller conveyor belts, designed for transporting sturdy cartons, were no match for the new, lightweight packaging material. Poly bags frequently got snagged on different parts of the machinery and often got caught between the rollers.

The resulting slow-downs in productivity had the exact opposite effect that the increased volume of orders demanded, complicating logistics operations.

The switchover from cartons to poly bags also affected the selection process for the type of sorter used in conveyor sortation systems. Instead of just knowing the rigidity of the cartons and the range of carton sizes, poly bag users need to compute not only the size of the bag but also the rigidity and size of the bag’s contents. Other considerations include how well the contents’ size aligns with the bag’s size.

Increased order volumes, faster delivery times and the evolution of packaging combined to create serious challenges for brick-and-mortar stores and emerging e-commerce businesses.

The Promise of Flexible Conveyor Sortation Systems

A major stumbling block was the fixed nature of many traditional conveyor sortation systems. The difficulties in modifying existing conveyors to meet the new demands prevented many retailers and distribution centers from immediately capitalizing on the e-commerce boom.

Some tried to overcome the inherent drawbacks of roller conveyors by implementing a tray or tote system in which totes or trays containing the poly-bagged orders traveled along the conveyors. This often required manual sorting to send the individual orders to their next destinations.

Flexibility and adaptability were the keys to solving the puzzle. Modular belt conveyors that are adjustable allowed material handlers to quickly respond to the changing demands of e-commerce. Highly configurable conveyor sortation systems reduce the amount of downtime required to switch up operations.

For instance, say a distribution center wants to switch a conveyor sorter from an accumulation function to transportation. Modular components can be substituted to accomplish the change in a relatively short period.

As another part of the solution, many distribution centers looked to automation. Material handling companies found they could overcome challenges by implementing automated systems that allowed them to more easily accommodate their customers’ evolving needs.

The Promise of Flexible Conveyor Sortation Systems

Today’s conveyor sortation systems need to be nimble, ready to adapt to the realities of any situation. Automation and modular construction are the keys to brick-and-mortar stores and e-commerce businesses making the transition.

The best conveyor sortation systems will offer crucial functionalities, like the ability to:

Custom-designed, automated e-commerce conveyors are leading the way with capabilities such as re-orienting and directional feeding.

Thanks to important conveyor sorter innovations, distribution centers can now easily move their material. E-commerce businesses have flourished in these new conveying environments. Forward-looking conveyor manufacturers have made all the difference in managing the ever-changing e-commerce landscape.

Conveyor Sortation Systems That Meet Your Needs

Span Tech understands the requirements of today’s e-commerce businesses. Plus, we have years of experience engineering conveyors for each customer’s specific operation. We can design automated conveyor sortation systems that accumulate, divert, discharge and sort your products in the exact fashion you require. Our wide range of equipment includes vertical conveyors and cross-belt systems for the easy transfer of bagged items.

Contact us today for the conveyor sortation system that keeps your business moving.