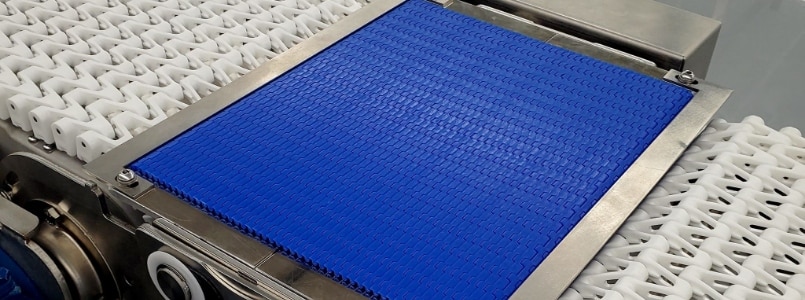

Understanding Accumulation Conveyor Systems

An accumulation conveyor is an integral part of a material handling system, designed to hold or ‘accumulate’ products in place until downstream processing is ready to continue. It acts as a buffer, maintaining a steady flow of items while preventing any damage that might occur from collision or pile-up. It’s an ingenious answer to managing pauses in workflows without stopping the entire production line, allowing for a controlled release of products.

Types of Accumulation Conveyors

Accumulation conveyors come in various forms, each tailored to suit different operational demands:

- Zero Pressure Accumulation Conveyors: These conveyors ensure that products do not touch each other while they accumulate by using electronic sensors and zones. Ideal for handling fragile goods, they prevent damage by controlling the pressure exerted on the items.

- Minimum Pressure Accumulation Conveyors: Slightly touching, the products on these conveyors accumulate with minimal contact, thanks to the careful regulation of the drive pressure. It’s a balance between the gentle handling of items and the need for a continuous flow.

- Contact Accumulation Conveyors: As the name suggests, these allow products to make contact in accumulation areas but with controlled pressure. They are typically used when product damage is not a concern and where simplicity and cost-effectiveness are prioritized.

Each type has its own niche, addressing specific challenges of product flow and accumulation in diverse environments. Span Tech’s accumulation conveyors are designed to integrate seamlessly with your existing systems, ensuring that whatever the type, products are handled with the care and precision that your operation requires.

How Does An Accumulation Conveyor Work?

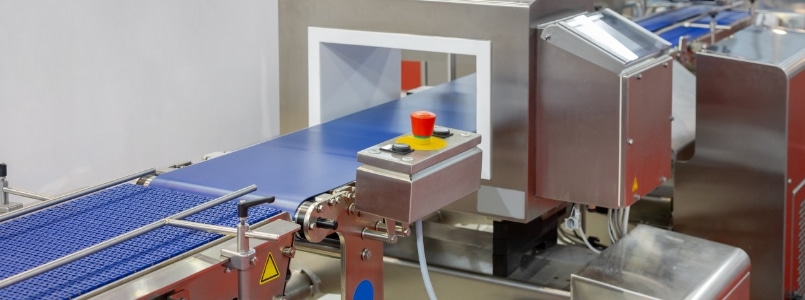

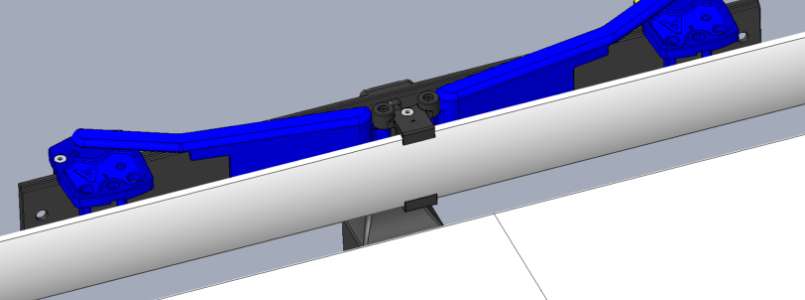

The inner workings of an accumulation conveyor system are a marvel of engineering. At its core, the system consists of a series of zones. Each zone is powered independently and can be activated or deactivated based on the conveyor’s need to accumulate products or allow them to pass through. When a zone becomes full, the conveyor halts the movement of products into that zone, thus preventing a backlog. Once the downstream process is ready, the zone is reactivated, and products continue on their journey. This methodical approach to product handling ensures a smooth operation, keeping the workflow balanced and efficient.

Span Tech’s accumulation conveyors refine this process further with state-of-the-art sensors and controls, enabling precise handling and movement of products with minimal supervision.

Accumulation Zones Explained

Accumulation zones are pivotal to the functionality of these conveyors. Each zone acts as a designated space where products can dwell temporarily. The length and number of these zones can vary, depending on the product size and the required accumulation capacity. Span Tech designs these zones with customization in mind, allowing for adjustments that align with your specific product dimensions and throughput requirements.

A critical aspect of these zones is the accumulation logic — the set of rules that determines when products should move or stay. The logic is programmed to suit the production needs, whether it’s to prevent products from touching or to allow a slight buffer. The intricacy of this system is what makes accumulation conveyors an accumulation marvel, effortlessly balancing product flow and storage.

The Role of Accumulation Conveyor Systems in Industries

Accumulation conveyor systems are not confined to a single industry but are instead a versatile asset across numerous sectors. Here are just a few of the applications of accumulation conveyor systems:

- In the food and beverage industry, these conveyors handle anything from packaged goods to raw food items, where maintaining product integrity is crucial.

- The pharmaceutical sector benefits from the delicate touch of zero-pressure accumulation conveyors, ensuring that sensitive products are not compromised.

- In warehousing and distribution, accumulation conveyors manage a wide variety of goods, adapting to different weights and sizes, and facilitating sorting and packaging processes.

- Automotive manufacturers utilize these systems for parts assembly lines, where timed and precise movement of components is essential.

Span Tech’s conveyors are designed with these diverse applications in mind, ensuring that no matter the industry, there is an accumulation solution that can be tailored to meet the needs.

Benefits of Using Accumulation Conveyors

The strategic integration of accumulation conveyor systems into your production line can yield numerous benefits that directly contribute to operational success and efficiency.

Streamlined Operations

Accumulation conveyors can create a more streamlined process, reducing bottlenecks and allowing for a continuous flow of products. This is crucial in preventing the domino effect that can occur when one section of the production line slows down or stops, ensuring that other parts can continue to operate without interruption. Span Tech’s accumulation conveyors are adept at creating a seamless operational flow that is both resilient and adaptable to the changing demands of production schedules.

Increased Efficiency and Productivity

By precisely managing the flow of goods, accumulation conveyor systems can significantly increase the efficiency and productivity of a production line. This is achieved by minimizing downtime and enhancing the synchronization between different stages of the manufacturing process. Span Tech’s conveyor solutions are engineered to maximize these efficiencies, providing businesses with the means to scale operations and increase throughput without compromising quality or performance.

Enhanced Product Handling

Sensitive or fragile products require careful handling to prevent damage and waste, and accumulation conveyors provide this gentle touch. By allowing for the controlled movement and accumulation of products, these systems minimize the potential for collisions and ensure that items remain in pristine condition throughout the production cycle. Span Tech’s conveyors are particularly noted for their gentle handling, ensuring that products remain unscathed and consumer satisfaction is maintained.

Accumulation Conveyor Systems from Span Tech

When choosing an accumulation conveyor system, selecting a provider with a robust track record of innovative and reliable solutions is essential. Span Tech has earned a reputation as a leader in the field, offering a suite of benefits with our conveyor solutions.

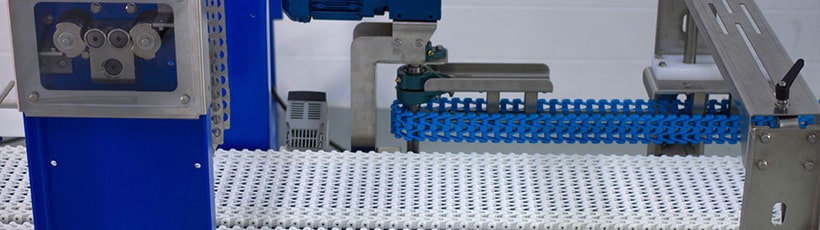

Span Tech’s Unique Conveyor Solutions

Span Tech offers a wide range of accumulation conveyors designed with precision, incorporating advanced technologies that provide smooth and efficient product transfers. With a focus on durability, Span Tech’s sorting conveyor systems are built to withstand the rigors of continuous industrial use, ensuring long-term reliability.

Customization and Flexibility

One size does not fit all when it comes to accumulation conveyors. Span Tech recognizes this and specializes in custom-designed conveyor systems that are tailored to meet the unique needs of each client. Whether you need a system that integrates with an existing production line or a completely new setup, we can provide a bespoke solution that fits seamlessly with your operations.

Support and Maintenance

A conveyor system is a significant investment, and Span Tech is dedicated to ensuring that this investment is protected. With a comprehensive support and maintenance program, clients can expect prompt assistance and service to maintain the optimal performance of their accumulation conveyors. Our commitment to customer service ensures that any issues are resolved quickly and efficiently, minimizing any potential downtime.

Span Tech’s accumulation conveyors deliver tangible benefits, making them an asset for any industry looking to enhance their production processes. The attention to detail and commitment to quality support positions Span Tech as a preferred partner for businesses aiming to optimize their operational flow with advanced conveyor solutions.

Frequently Asked Questions About Accumulation Conveyor Systems

What Are the Different Types of Conveyor Rollers?

Conveyor rollers come in several types, each designed for specific applications and load requirements:

Gravity Rollers: These rely on gravity to move products and are typically used in manual loading or unloading scenarios.- Driven Rollers: Part of a powered roller system, these are connected to a motor via chains or belts and actively move the product along the conveyor.

- Accumulation Rollers: Designed to allow products to accumulate along the conveyor while the belt continues to move, often featuring a clutch-like mechanism.

- Impact Rollers: Positioned at conveyor loading points, impact rollers are designed to absorb the shock of heavy materials falling onto the belt.

- Tapered Rollers: Commonly used on curves in conveyor systems, tapered rollers facilitate smooth product transfer through turns.

- Grooved Rollers: These can be used with round belts or ropes to move products and are often seen in sorting or diverging systems.

How Do Accumulation Conveyor Systems Improve Productivity?

Accumulation conveyor systems improve productivity by:

- Reducing Downtime: They allow the conveyor to continue running even when downstream processes need to pause, preventing stoppages that can lead to bottlenecks.

- Enhancing Flow Control: They enable the smooth regulation of product flow, ensuring a consistent supply of goods to each stage of the production or packaging process.

- Minimizing Product Damage: By allowing products to accumulate without pressure or contact, they reduce the risk of damage to fragile items, maintaining product integrity.

- Improving Synchronization: They facilitate the synchronization between different sections of the production line, making it easier to manage timing and handling of products.

Increase Productivity With Span Tech Accumulation Conveyor Systems

Are you ready to revolutionize your production line with unmatched efficiency and precision? Span Tech’s accumulation conveyor systems are the key to unlocking seamless operation and scalability in your business. Don’t let bottlenecks and inefficiencies hold you back. Contact Span Tech today to find out how our innovative accumulation conveyor systems can elevate your operations to the next level. Experience the Span Tech difference and ensure that your products move smarter, not harder.