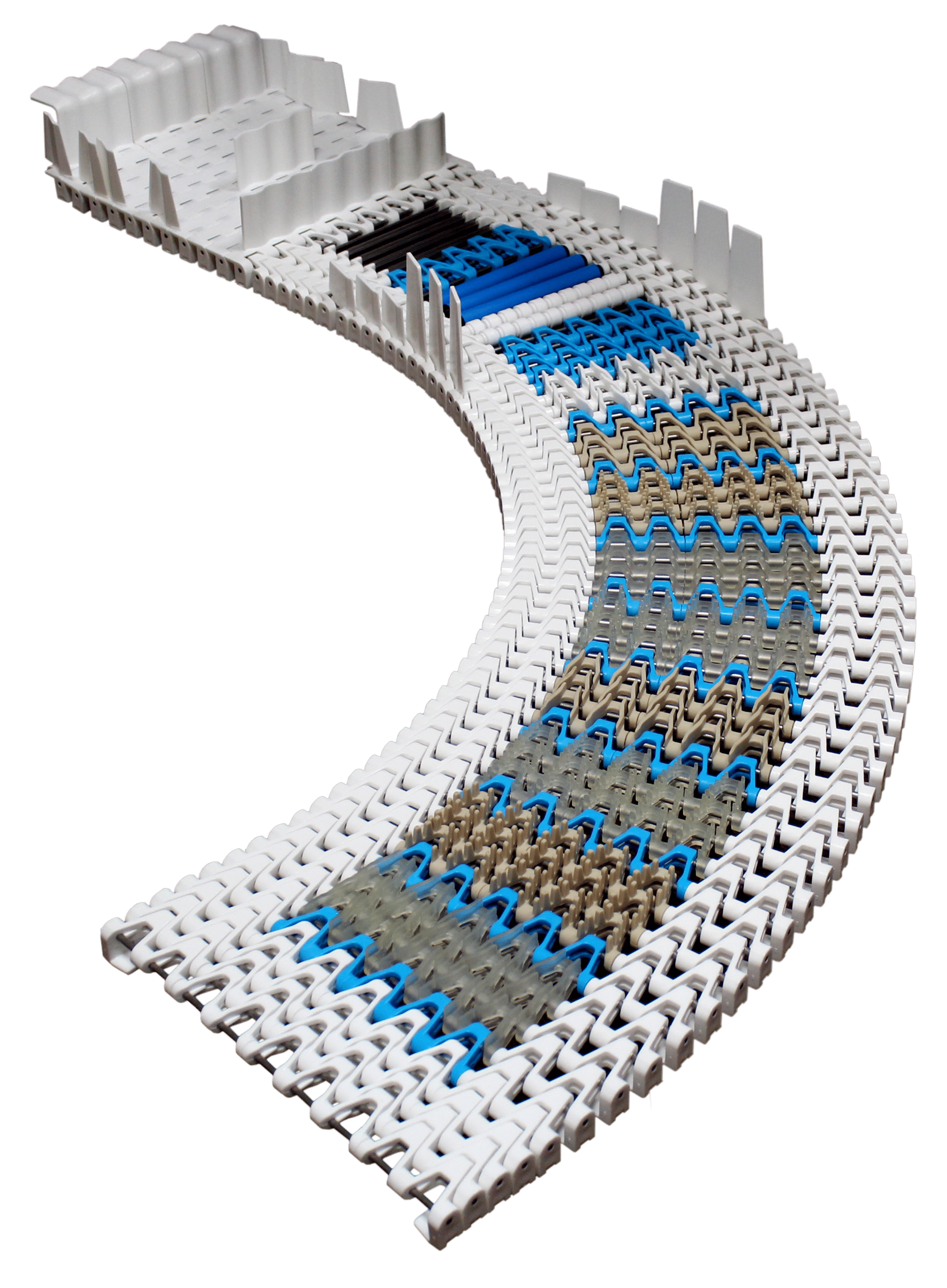

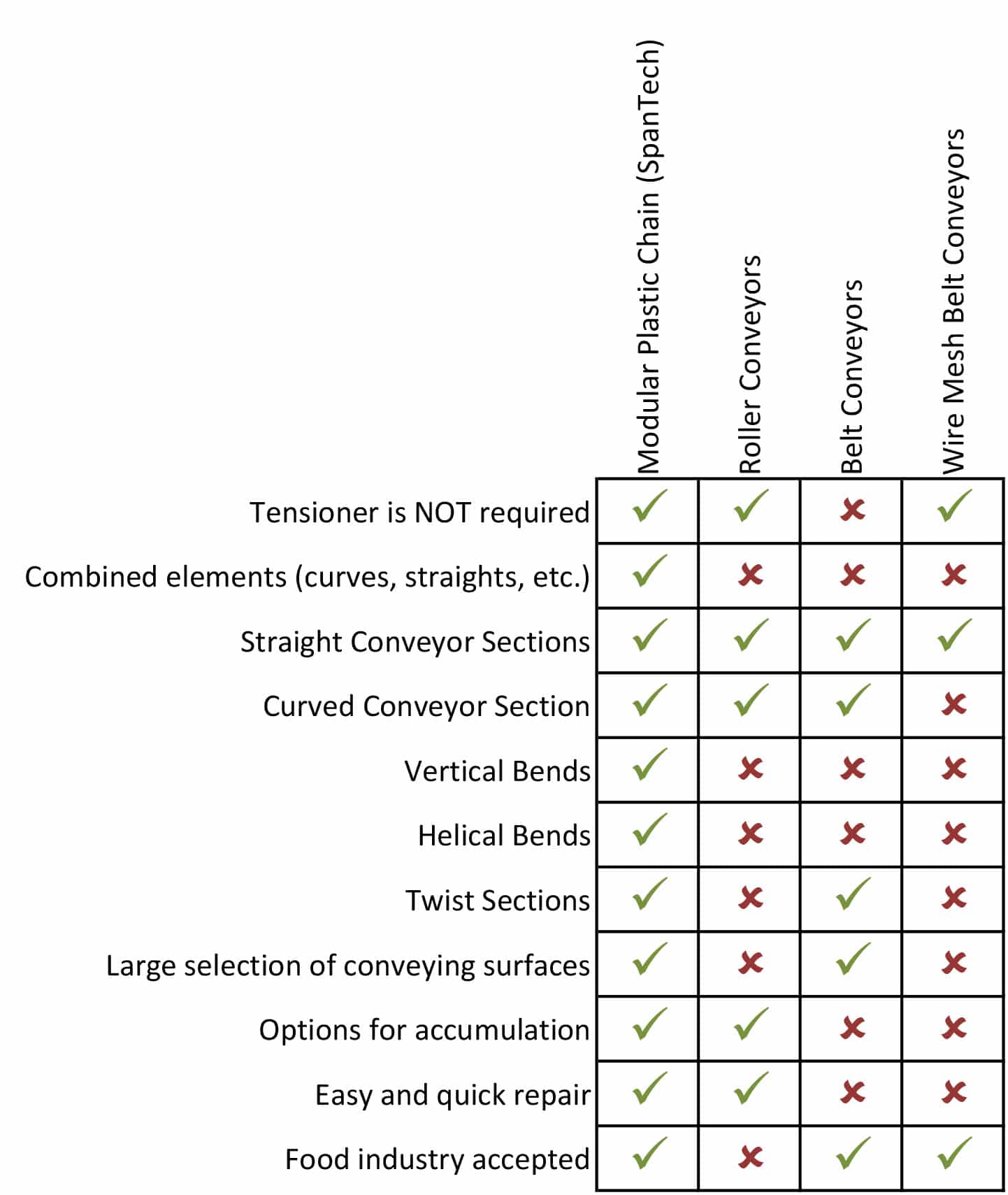

When purchasing your new modular, rebuildable and durable conveyors from Span Tech, you have a lot of options. Our patented plastic conveyor chain designs provide solutions applicable to a wide variety of products and industries. But which type is right for your various assembly lines and the end product? There are a few questions you should ask yourself that can aid in your decision-making process.

How delicate or small are the materials you’re handling?

If you’re manufacturing delicate products, it’s extremely important to have the proper conveyor chain types that won’t crush, tip or break anything during the process. It can also be difficult to protect small items or to handle small parts while on a conveyor system. That’s why you need a plastic chain conveyor belt that can securely handle and transport small items.

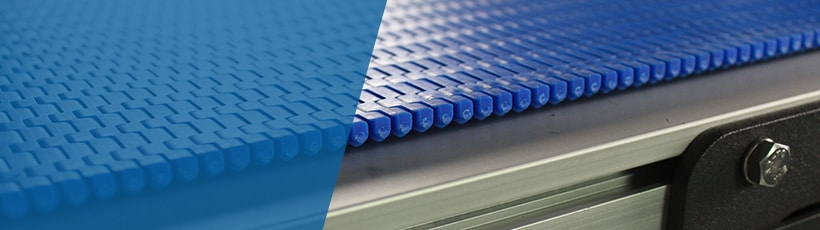

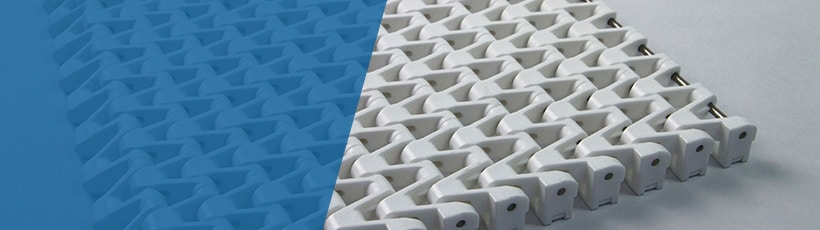

Pillow Top. The Pillow Top chain conveyors can handle the most delicate of products with ease and extreme precision. Perfect for food production facilities, this chain conveyor has the ability to transfer very small products that can get caught or snagged in more traditional conveyors.

MiniLink. For moving small products with extreme care, the MiniLink plastic conveyor chain is the ideal choice. This conveyor combines the functionality of a traditional conveyor system with a compact cross section for easy, delicate handling.

Do your materials need to cool or cure while being conveyed?

Whether your products need to be cooled or cured while on the production line, it’s vital that you have a plastic chain conveyor that can withstand extreme temperatures.

MaxiSpan. The innovative MaxiSpan chain has an adaptable design and remains a top choice thanks to its product-cooling capabilities. This plastic conveyor chain is available in materials that are resistant to most chemicals and constant temperatures ranging from -40℉ to 220℉.

50mm SuperTight. When manufacturing products that need to be cooled or dried on the production line, an open design is key to allow for good airflow. The 50mm SuperTight plastic conveyor chain has just that.

J-Trax. Add efficiency and ease to the process of food and beverage production with the J-Trax system. This functional design features open rods that allow for the rapid cooling of bakery items. With a variety of applications, the J-Trax can be used to cool, bread and batter, enrobe, deposit, drain, dewater and dry.

How messy are the materials you’re handling?

When dealing with particularly messy products, you need a plastic chain conveyor belt that allows excess liquids or remnants to sift through the chains.

MaxiSpan. With its 75 percent open design, the MaxiSpan also allows liquids and debris to fall through the conveyor chain, which equates to less cleanup and less downtime.

J-Trax. The J-Trax conveyor system’s open rod design also allows any excess material to fall through in order to prevent accumulated or hidden debris. The J-Trax design is fully washdown rated with stainless steel, making it easy to clean and sanitize for those producing messier products.

Will your conveyor need to make sharp turns?

The ability for a conveyor to make sharp turns cannot be underestimated. Whether you’re dealing with a tight space or a specialty production line, having a conveyor system that can make sharp turns is a huge asset.

50mm SuperTight. In addition to having good airflow, the 50mm SuperTight chain has the tightest turning radius on the market today. This means that it can cut tight corners in any conveyor layout making it super versatile for any facility.

Pillow Top. The Pillow Top conveyor also offers one of the tightest turning radii on the market for its chain width. In fact, the Pillow Top is actually based off of the 50mm SuperTight design and is a direct replacement for any 50 mm SuperTight conveyor.

SuperTight. Offering an extremely tight turning radius, the SuperTight chain is perfect for anyone looking for a smaller horizontal turning radius. Make any tight turn easily and securely.

Let Span Tech Find the Perfect Conveyor Solution for Your Needs

It’s always best to consult with an expert for a custom solution, and we can help. Span Tech has a large variety of packaging conveyors to suit your needs. Have a question or need more information? Contact our customer service team to learn more about our conveyor features and to start your free estimate today.